"Biomass resources" that also contribute to global warming countermeasures

Updated by Taro Kamagata on July 07, 2025, 5:05 PM JST

Taro KAMAGATA

(Platinum Initiative Network, Inc.

After graduating from Keio University with a degree in economics in 1982, he joined Toppan Printing Co. In 1988, he moved to Mitsubishi Research Institute, where he was in charge of urban and regional management and public-private partnerships (PPP, PFI, etc.). He later became an executive officer and served as Director of the Regional Management Research Division, Director of the Platinum Society Research Division, and Managing Executive Officer and General Manager of the Research and Development Division, etc. He was seconded to Mitsubishi Research Institute DCS as Senior Managing Director in 2018, retired as an officer of Mitsubishi Research Institute in 2021, and became an advisor to Platinum Initiative Network in 2022. Leader of the Secretariat of the Platinum Forest Industry Initiative.

last timeAs a review of the "The Chemical Industry in Japan," let's take another look at the manufacturing process of the chemical industry in Japan, from raw materials to the production of chemical products.

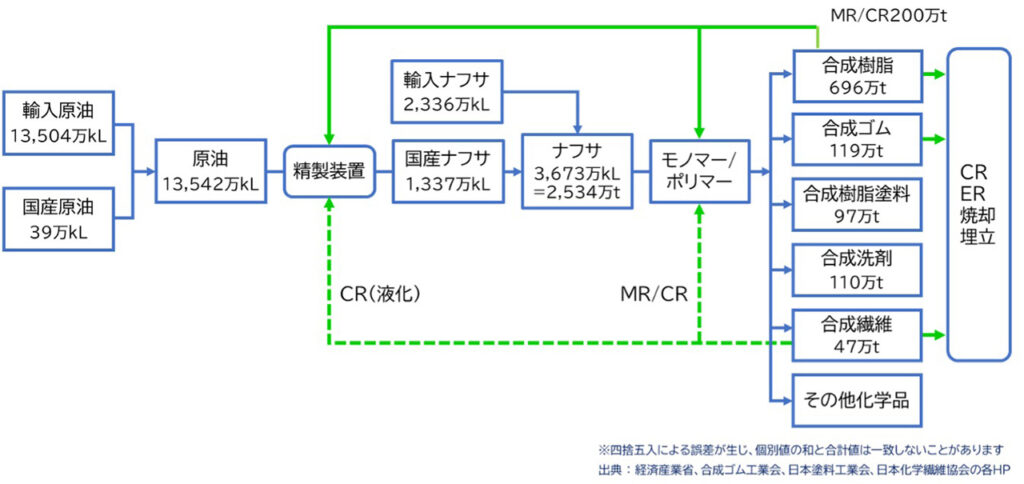

Japan's chemical products are produced mainly from domestically produced naphtha refined from imported crude oil (135.04 million kL), which is a fossil resource, and imported naphtha refined overseas (23.36 million kL). Only 390,000 kL is domestically produced crude oil. Recycled raw materials account for less than 30% of commercialized plastics.

Of the chemical products produced, synthetic resins (so-called plastics) account for approximately two-thirds of the total, at 6.96 million tons. Other chemical products include synthetic rubber, paints, detergents, fibers, and many others.

Although recycling efforts for plastics have made progress in recent years, product groups such as paints and detergents, which account for about one-third of non-plastic products, are difficult to recycle and are not expected to be utilized as reusable raw materials. In addition, even if plastics are recycled, weight loss occurs during manufacturing, making it difficult to reproduce 100%.

Therefore, even if all plastics could be collected separately and recycled, it is expected that only about one-third of the total chemical products could be covered.

Against this background, as we discussed in the previous issue, the use of biomass resources is essential for the conversion of feedstocks to decarbonize the chemical industry.

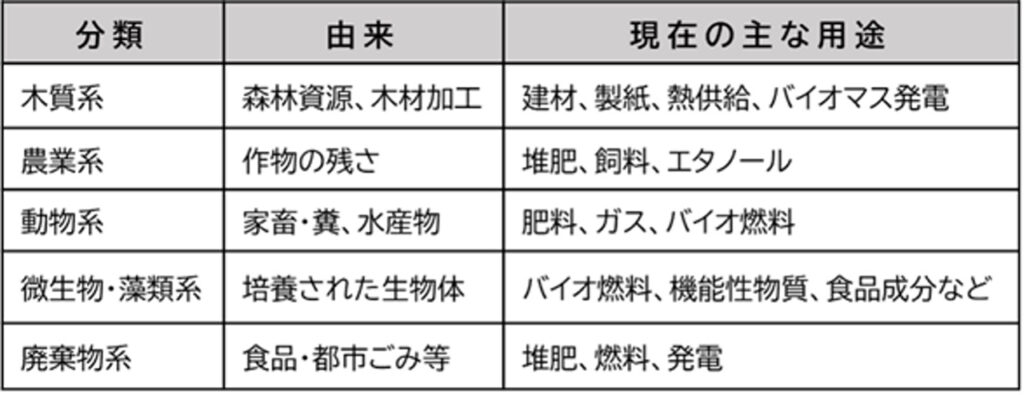

So what is biomass? Biomass refers to resources derived from living organisms, such as plants and animals, that have been grown by the energy of sunlight. Biomass includes agricultural, woody, animal, and microorganism/algal species, and their wastes can also be used as biomass resources.

The etymology of the word "biomass" is a combination of "bio" (organism) and "mass" (substance/quantity), and it describes the amount of material or resources of biological origin. The main characteristics are as follows

<Renewable resources

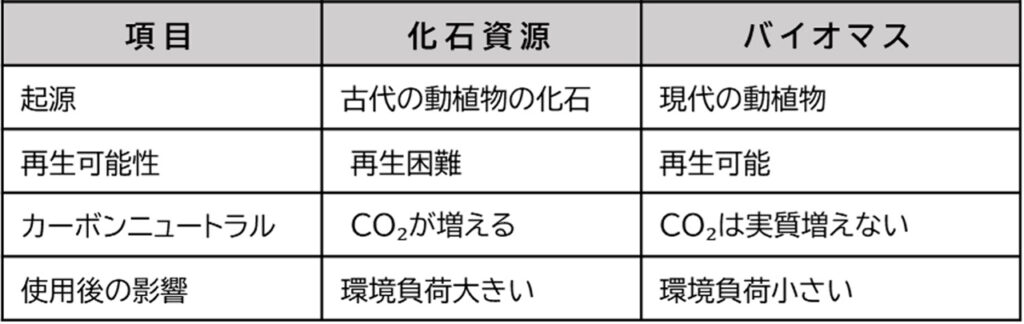

Fossil resources are finite resources that, once used, take tens of millions of years or more to regenerate. Biomass, on the other hand, is a recyclable resource that can be regenerated in a relatively short period of time because it is derived from plants, animals, and other living organisms. Unlike fossil resources, biomass has the advantage of not being easily depleted.

<Carbon Neutral

Plants absorb CO2 from the atmosphere during their growth and store carbon in their bodies. When this is burned and decomposed for use as energy, the amount of CO2 emitted is equal to the amount absorbed during growth, so there is no new increase in CO2 in the atmosphere. On the other hand, CO2 generated from burning fossil resources takes a very long time to regenerate, thus increasing CO2 in the atmosphere and causing global warming.

<Contribution to the fight against global warming

Because it is renewable and carbon neutral, it is attracting attention as an alternative resource to fossil resources, which are difficult to regenerate and emit CO2, thus contributing to the fight against global warming.

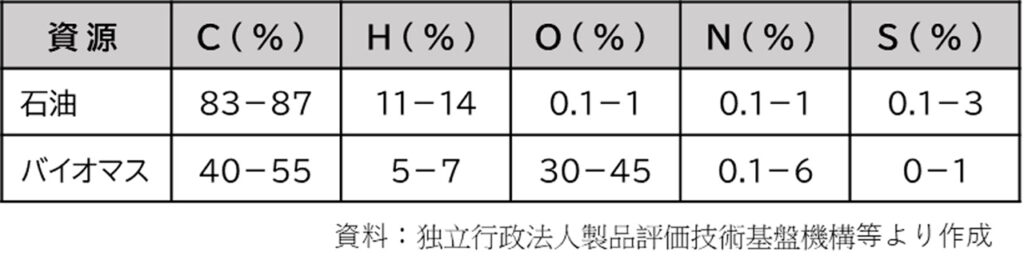

Many chemical materials, including plastics, are composed of organic compounds with a carbon (C) and hydrogen (H) backbone. Therefore, petroleum, which is rich in carbon and hydrogen, is currently the primary raw material.

First, petroleum is refined (heated and distilled) to obtain a liquid raw material called "naphtha (e.g., C6H14 or C6H12). Cracking (high-temperature decomposition) of naphtha produces monomers such as ethylene (C2H4) and propylene (C3H6). Polymerization of these monomers produces "polymers" (polymerized materials), which are used as materials for plastics and other chemical products. The resulting polymers (synthetic resins) are processed into various product forms by applying heat or pressure.

It is important to note that the "source" of the material is carbon. In other words, chemical products can be made from raw materials other than petroleum as long as carbon-containing compounds can be obtained. In other words, it is possible to produce chemical products such as plastics from carbon-rich biomass resources.

As described above, it is theoretically possible to manufacture chemical products using biomass resources. Therefore, with the aim of decarbonizing the chemical industry, the Platinum Forest Industry Initiative aims to shift the chemical product manufacturing process, which has been dependent on fossil resources, to a sustainable manufacturing process that focuses on recycled and biomass raw materials.

So, is it actually feasible? In the next and subsequent issues, we will discuss technological trends and specific company initiatives related to the production of chemical products using biomass resources. (Taro Kamagata, Advisor, Platinum Initiative Network)

The book of the same title as this web media, "Forest Circular Economy" (edited by Hiroshi Komiyama) was published by Heibonsha on August 5, 2025. The book proposes a redesign of the economy, institutions, and local communities based on the three pillars of biomass chemistry, wooden cities, and forestry innovation in the cycle of "cutting, using, planting, and nurturing" forests. This practical book provides a point of contact between concepts and examples for those involved in policy making, social implementation, and the creation of businesses that make use of local resources.

View on Amazon

The "Forest Circular Economy" is the key to regional development and a decarbonized society. We will hold a webinar "Creating the Future through Forest Circulation" to introduce the forefront of this concept. The speakers will be 10 practitioners from industry, government, and academia, including Yasunao Kobayashi. They will discuss the transformation brought about by the utilization of forest resources, including advanced case studies from across Japan.

Date: Thursday, July 10, 2025, 13:00-17:00

Format: Online (free of charge, registration required)

*It is also possible to watch only specific sessions.

Platinum Initiative Network and Platinum Forest Industry Initiative "Forest Circular Economy" Editorial Department

● For details and application, click here.