Expanding possibilities with shape-retaining cellulose material that takes advantage of wood's excellent natural structure

Updated by Sachio Horikawa on July 08, 2025, 8:11 PM JST

Yoshiki HORIKAWA

Graduate School of Tokyo University of Agriculture and Technology

Professor, Graduate School of Agriculture, Tokyo University of Agriculture and Technology / Specialized in wood science and cellulose science. Especially, he studies the crystal structure of cellulose synthesized by various organisms and its diversity. Publications: Practical Guide to Forest and Forestry, 2nd edition, revised edition (co-authored, Asakura Shoten, 2024), Formation of Wood Quality, 3rd edition (co-authored, Kaiseisha, 2024), etc.

The Paris Agreement was adopted at COP21 in Paris, France in December 2015. This agreement requires all participating countries to set greenhouse gas reduction targets. In 2020, then Prime Minister Kan declared Japan's goal of achieving "zero overall greenhouse gas emissions by 2050," or carbon neutrality. The phrase "zero overall" is important because it may be difficult to completely eliminate carbon dioxide emissions in some industries. Therefore, "negative emission" efforts to absorb and remove emitted carbon dioxide are important. Through such efforts, it is possible to offset emissions and regard them as virtually zero, which is also recognized in the Paris Agreement.

One of the most common methods of negative emissions is tree planting. Planted seedlings absorb and fix carbon dioxide in the atmosphere through photosynthesis during their growth. It is estimated that a properly managed cedar plantation of about 40 years old accumulates about 302 tons of carbon dioxide per hectare (*1).

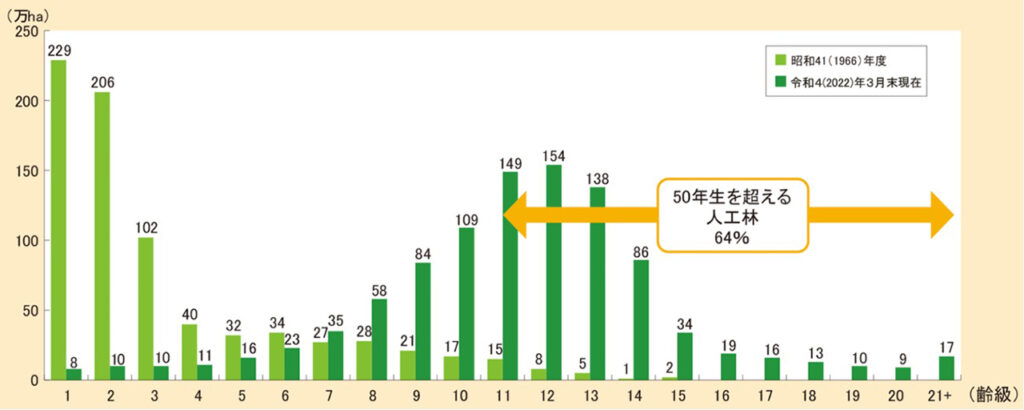

In general, young forests grow vigorously and thus fix a larger amount of carbon dioxide, but in mature forests, the amount of carbon dioxide emitted through respiration increases relative to the amount absorbed through photosynthesis, and the overall fixation rate gradually declines. In Japan, many of the planted forests planted after World War II are already over 50 years old (*2), and from the perspective of carbon dioxide absorption and fixation, it is important to cut down these trees and plant new ones (Figure 1).

The stable use of wood is crucial to promote tree harvesting and afforestation. Wood is used for a variety of purposes, including wooden houses, furniture, civil engineering materials, and paper, all of which remain above ground for a certain period of time with carbon fixed in them.

Carbon dioxide is emitted when it is used as fuel or disposed of or incinerated. Therefore, long-term use of wood and its components is important from the perspective of negative emissions. Furthermore, by returning the economic benefits of wood use to the cultivation and management of forests, an ideal carbon cycle can be established and a sustainable society can be realized.

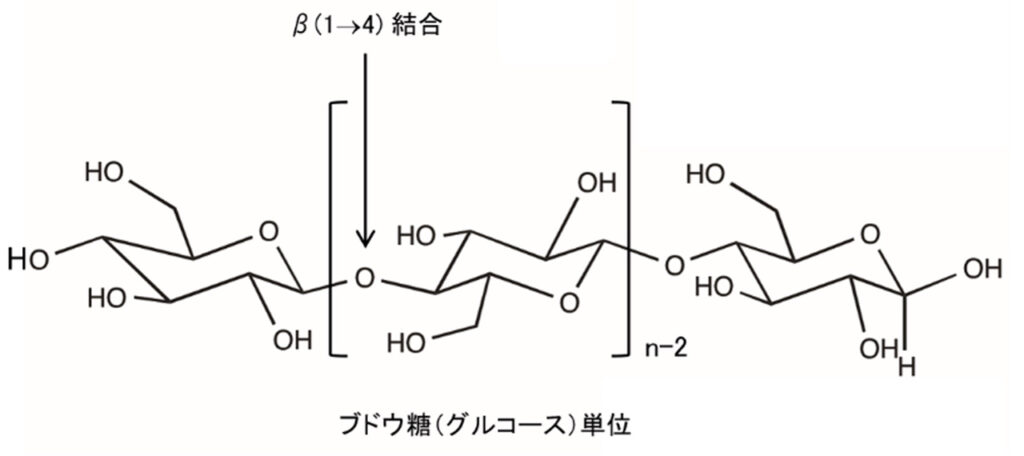

Cellulose is one of the major components of wood and is the most abundant organic material on earth. Here is a brief description of its chemical properties. Cellulose is a macromolecule, the monomer of which is glucose (Figure 2).

In other words, it is composed of the same monomers as the starch we eat. However, the bonding mode [β(1→4) bond] used to form a macromolecule is different from that of starch [α(1→4) bond], and the properties are also very different. While starch has a helical structure, cellulose has a linear molecular structure that is tightly packed to form fibers with a crystalline structure. These crystalline fibers are the source of cellulose's outstanding solid-state properties.

Humans have long utilized this biological resource for a wide variety of uses, including paper products, clothing, food, cosmetics, pharmaceuticals, and fuel. In each case, cellulose production involves the physical and chemical treatment of wood. In other words, cellulose is utilized in a way that removes the wood's natural structural characteristics.

The most important factor that enabled plants to advance from the underwater environment to the terrestrial environment and to grow to enormous size on the ground, defying gravity and drought, is the elaborate hierarchical structure that trees have formed within their bodies. Cellulose has a certain orientation and forms a complex with lignin and hemicellulose to construct cell walls, and the regular arrangement of these cells produces a superior structure called wood. It is this wood that supports the massive tree body and allows the tree to survive for more than 100 years.

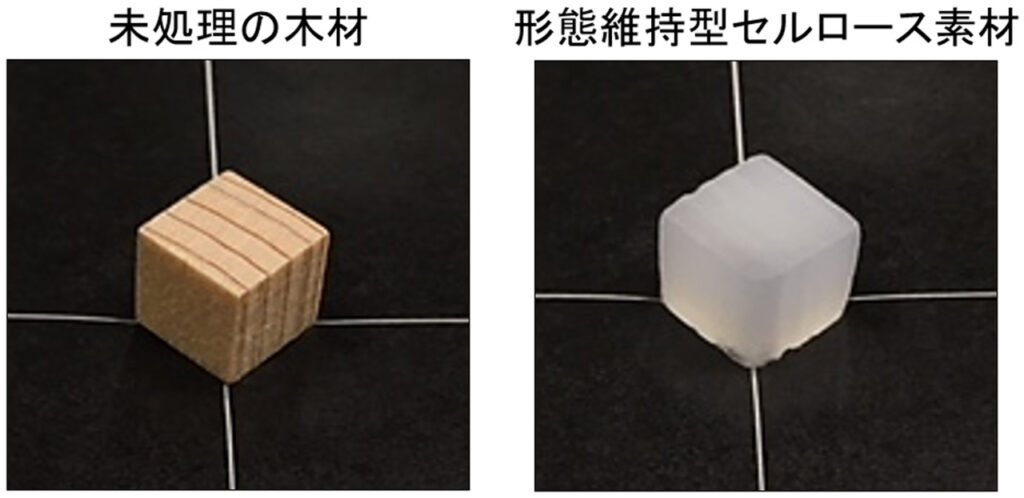

We have worked to create a cellulose material that retains this outstanding three-dimensional structure. As a result of extensive examination of chemical treatment conditions, we succeeded in developing a cellulose material that retains the form of cedar wood as shown in Figure 3 (Patent No. 6941328: Wood and method for producing wood) (*3).

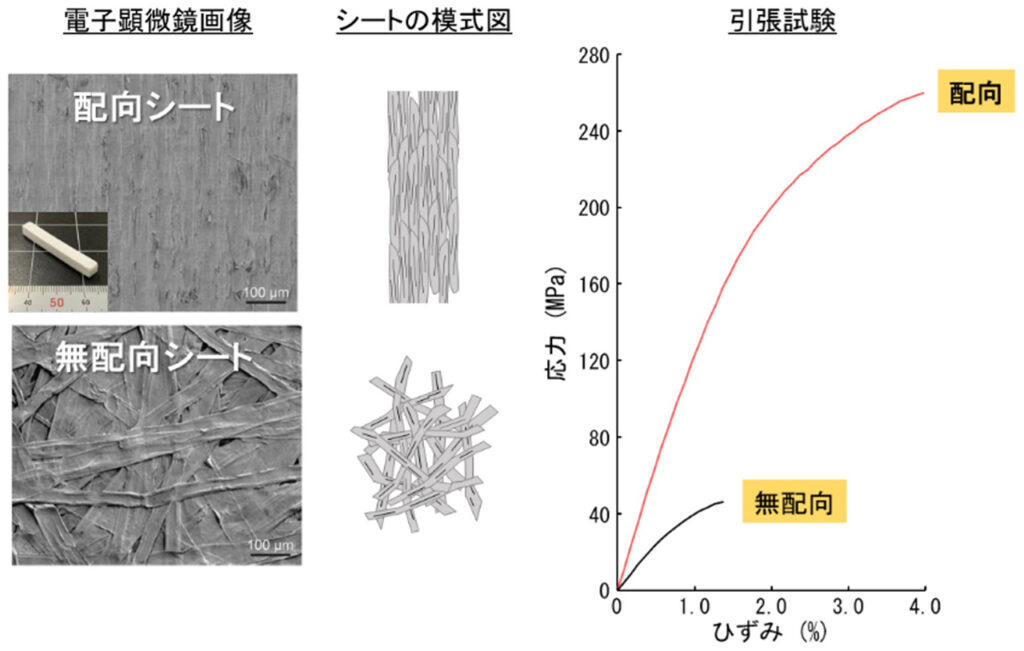

Here is an example from the viewpoint of material utilization. General cellulose sheets are made by laminating wood fibers after unraveling them into pieces, so the direction of the fibers is random. On the other hand, when cellulose material that maintains the form of wood is pressed as it is, a sheet with the same fiber direction is obtained. As a result of subjecting these sheets to tensile tests, we succeeded in producing a material that exhibits much higher strength than random sheets (Figure 4) (*4).

Furthermore, it is expected that materials with new functions can be developed by manufacturing from wood species with different tissue structures or by impregnating this morphology-retaining cellulose material with resins and other materials. These efforts will also contribute to the realization of carbon neutrality through negative emissions. (Professor Shosei Horikawa, Tokyo University of Agriculture and Technology Graduate School of Agriculture, Division of Environmental Resources Material Science)

■References

1) Naoki Masuhara, Supervisor (2022) Understanding Carbon Neutrality with 30 Keywords, JMA Management Center, pp. 126-129.

2)Forestry Agency (2024) Changes in Age Class Composition of Plantation Forests, 2024 White Paper on Forest and Forestry

3)Horikawa Y., Tsushima R., Noguchi K., Nakaba S., Funada R. (2020) Development of colorless wood via two-step delignification involving alcoholysis J Wood Sci, 66, Article number:37.

4)Kurei T., Hioki Y., Kose R., Nakaba S., Funada R., Horikawa Y. (2022) Effects of orientation and degree of polymerization on tensile properties in the Cellulose, 29, 2885-2898.