Paper and paperboard also function as social devices that "store and recycle carbon."

Updated by Ryota Kose on August 22, 2025, 7:45 PM JST

Ryota KOSE

Graduate School of Tokyo University of Agriculture and Technology

Associate Professor, Department of Environmental Resources and Materials Science, Graduate School of Agriculture, Tokyo University of Agriculture and Technology / Specialized in papermaking science and cellulose science, and has been conducting research to gain new knowledge on the manufacturing process and structure of paper, which has been produced for 2000 years, and on the advanced utilization of cellulose fiber from pulp fiber to cellulose nanofiber. He is also a member of the board of directors of the University of California, Berkeley.

The most familiar "forest-derived mass products" around us are probably paper and paperboard. Notepads, newspapers, wrapping paper, corrugated cardboard, beverage cartons--they all come in a variety of forms, but they are all deeply integrated into our daily lives through the processing and distribution of trees grown in forests and used not as lumber but as "fiber. After they have been used, they are collected and recycled, and reintegrated into the social cycle.

It is clear from the figures how large this "paper and paperboard" material is. Worldwide, the annual production of paper and paperboard is about 400 million tons, of which China, the United States, and Japan are the top producers. In Japan, paper and paperboard will be produced to the tune of about 23 million tons by 2022, and this will account for an extremely large share of domestic wood use. Compared to lumber, paper and paperboard is a short-cycle wood use that is part of a dynamic carbon cycle in human society.

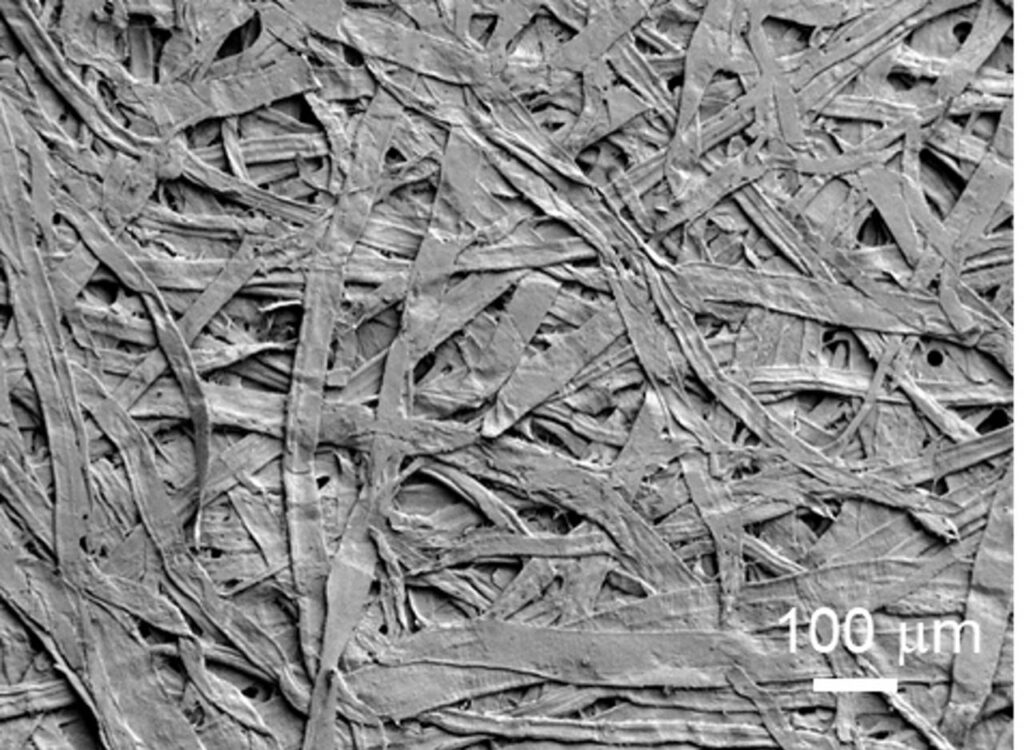

It is said that the method of paper production has remained virtually unchanged for more than 2,000 years. Plant-derived fibers are dispersed in water, spread thinly, intertwined to form layers, dehydrated under pressure, and finally dried - this series of processes is the basis of papermaking. This simple and essential process has been passed down throughout the world without being eliminated even in the face of today's advanced science and technology. The manufacturing process itself is a testament to the high adaptability of paper as a material to human society and the natural environment.

There is a growing movement to reconsider the characteristics of paper and paperboard from the perspective of "carbon absorption by forests = carbon cultivation," rather than as mere "industrial products. Forests fix atmospheric CO2 through photosynthesis during the growth process and store carbon in their trunks, branches, and leaves. Cutting down and using timber is often seen as deforestation, but in reality, a sustainable system of "carbon cultivation" can be established through systematic thinning and repeated main cutting and reforestation. In the paper manufacturing sector, a forest certification system is in place, and sustainable forest use is fundamental.

In this context, paper and paperboard do not simply consume wood, but function as "temporary storage containers within society" for carbon stored in forests. In terms of temporary storage of carbon within society, the high recycling rate of paper contributes to extending the period of time that carbon remains within society.

Moreover, over the years, functional improvements in paper and paperboard have continued. In recent years, for example, the development of applications for food packaging paper as a substitute for plastic, using pulp fiber micronized fibers as a barrier agent, has been active, and advanced materials such as cellulose nanofibers (CNF) have also been developed.

Our laboratory is also engaged in research to develop the potential of paper and paperboard as mass products for structural applications. Using flexural rigidity, a shape-dependent physical property, as an evaluation index, they have successfully produced a multilayer paperboard that exceeds the flexural rigidity of an aluminum plate 1 m wide and 2 mm thick (see Figure 2). We have also shown that by devising the arrangement of pulp fibers and CNF, it is possible to produce a multilayer paperboard that has the same flexural rigidity as a 3mm-thick polypropylene (PP) board, but is 20% lighter (*1). Currently, we are strategically collecting basic data on mechanical properties and simulating deformation behavior in order to look ahead to the application of multilayer paperboard.

Paper and paperboard still have unique value in the digital age. The feel of touch, the comfort of writing, and the visual calmness - these are information experiences that appeal to the five senses, and continue to be media that stimulate human creativity. The material of paper also has the potential to build a circular economy of local production for local consumption, using wood from different regions. In particular, it can be a tool to draw out the diverse values of forest resources, especially in its ability to utilize thinned wood and low-quality wood.

After all, paper and paperboard are not "disposable tools" but are already functioning in modern society as "carbon storage and circulation devices. The role of paper and paperboard made from wood in a forest-based circular economy will become increasingly important in the future. (Ryota Ose, Associate Professor, Tokyo University of Agriculture and Technology)

*Reference 1

Ayumika Karasawa, Keisuke Ando, Dokuho Matsubara, Takuma Kozono, Ryota Ose, Development of Lightweight Paperboard Using Mass-produced Microfiber, Proceedings of the 92nd Conference on Pulp and Paper Research, p91, 2025.