Updated by "Forest Circular Economy" Editorial Board on November 18, 2025, 8:20 PM JST

Editorial Board, Forest Circular Economy

Forestcircularity-editor

We aim to realize "Vision 2050: Japan Shines, Forest Circular Economy" promoted by the Platinum Forest Industry Initiative. We will disseminate ideas and initiatives to promote biomass chemistry, realize woody and lumbery communities, and encourage innovation in the forestry industry in order to fully utilize forest resources to decarbonize the economy, strengthen economic security, and create local communities.

Why hasn't productivity in the forestry industry increased? As labor shortages and costs continue to rise, the question is how to change the system on the ground and how to sustain it as a regional industry. On October 17, the Platinum Forest Industry Initiative, which has moved from the proposal phase to the implementation phase, held its regular meeting in Tokyo under the theme of "Improving Material Production Efficiency and Production Management System. The speaker was Mr. Kimiya Shibata, Representative Director of Shibata Sangyo (Ichinohe Town, Iwate Prefecture), a company that handles everything from afforestation to logging, transportation, sawmilling, processing, wood fuel, and construction. The company's goal is to develop Japan's forestry industry into a world-class industry by combining European production systems with DX technology, in which Japan has an advantage. In his speech, he gave hints on how to envision the future of the forestry industry based on both DX and regional circulation.

What Shibata Sangyo is working on is a radical improvement of the material production process. The conventional Japanese forestry industry is based on the "tree-length system," in which long logs are collected and transported after harvesting, and later cut into pieces at the mill. The first pillar of the company's efforts to improve material production efficiency is the introduction of a European-style cut-to-length (CTL) system. This system, which enables continuous operations from felling to pruning, cutting, and collection of lumber, has dramatically improved productivity at the site by enabling two units and two people to complete tasks that previously required four to five units and four people.

The company compared and verified forestry machinery from Austria and Sweden, taking into account the conditions in Iwate, which has many steep terrains. Finally, the company selected and purchased a small, high-performance machine suited to Japan's terrain and timber diameter. The company has now established an affiliated company and has begun selling the machines to other forestry companies in Japan.

President Shibata recalls, "We couldn't find a machine that could be used in Japan. So we found it ourselves and brought it here," he recalls.

According to the company, labor productivity has improved two to four times from 11 to 14 cubic meters per man-day in the past to 28 to 45 cubic meters per man-day after the introduction of the CTL system. Material production costs have also been reduced by 400 to 600 yen per cubic meter.

On the other hand, machinery costs temporarily increased 1.6 times, but the efficiency gains are said to be sufficient to absorb the increase. Iwate Prefecture's analysis also rated the company's productivity as "as high as in Austria," quantitatively demonstrating the results of the on-site reforms.

The key to this efficiency is the use of two harvesters and a forwarder to complete the entire process from felling to slashing and hauling out. Especially on slopes exceeding 30 degrees, the harvester with winch is utilized to fell and cut down trees while they are still standing. This allows felling without the need to build as many work paths as in the past, thereby reducing environmental impact and improving work safety.

The CTL system is the starting point for a sustainable forestry industry. This is the starting point for sustainable forestry," emphasizes President Shibata, adding that the CTL system is not merely a machine introduction, but a conversion device to "profitable forestry while protecting people.

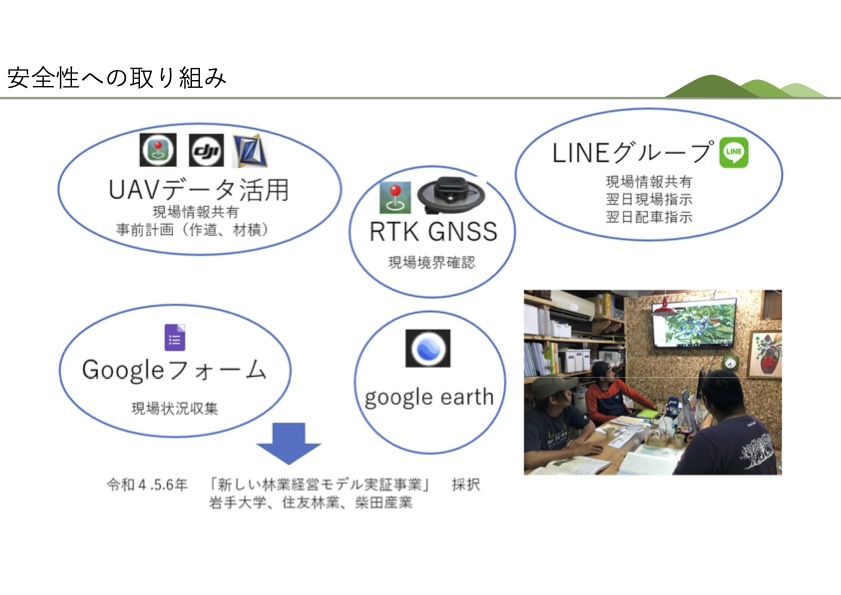

Shibata Sangyo is also working to reform its management system by “visualizing” the work site. The company has established a system to optimize on-site work, which used to rely on the experience and intuition of skilled team leaders, based on data. In collaboration with Iwate University, the company introduced forest resource analysis using laser drones (UAV LiDAR). Topographic data (DEM) of the mountain forest was acquired, and the amount of accumulation, slope, and forest road conditions were quantified. This made it possible to automatically calculate the best routes for work paths, and to reproduce some of the “experience” that had been gained by the team leader by looking at the terrain.

President Shibata says, "A veteran team leader can tell by looking at the mountain, but a newcomer cannot. If the data becomes a landmark, there will be less hesitation," he says.

The company also jointly developed a site management application. Both the harvester and forwarder are equipped with tablets that display logging locations and collection routes on a cloud-based GIS. This allows the location and quantity of logs to be visualized even in the mountains.

Sharing data allows for quicker direction and support. Instead of intuition and experience, numbers are driving the team," states President Shibata. This visualization has brought a real sense of efficiency, as well as innovation in terms of safety management and traceability.

The introduction of DX technology is not only improving productivity, but also fundamentally changing the "working environment" and "human resource development" in the forestry industry. At Shibata Sangyo, on-site data shared on the cloud supports both human resource development and decision-making. Even new employees can immediately make decisions on work policies by looking at plans based on drone analysis and on-site information from the management application, making it possible to manage teams that do not rely solely on the experience of experienced workers.

In addition, boundary confirmation by RTK-GNSS, which utilizes GPS positioning, achieves centimeter-level accuracy. This prevents boundary problems and enhances safety. Boundary surveying equipment, which conventionally cost around 2 million yen, has been replaced by consumer RTK-GNSS in the 100,000-yen range.

In the past, specialized equipment was necessary, but the important thing is for people in the field to master the technology as if it were their own,“ says President Shibata. President Shibata regards ”low-cost efficiency“ as the key to sustaining the forestry industry in rural areas.

Even with the advancement of digitalization, it is people who ultimately support the forestry industry. Shibata Sangyo, in collaboration with Iwate University, Sumitomo Forestry, and Fotek of Hokkaido, has standardized data from job sites, developed training programs, created an environment in which even newcomers can make decisions based on data, and rebuilt a system for passing on skills.

It is the people onsite who use the technology. As President Shibata says, the company's DX functions as a tool for “making the best use of people,” not as a “replacement of people.

Shibata Sangyo's management model is characterized by the fact that it is designed not only to produce materials, but also to "exit. The company has put in place a system to recycle the wood and by-products obtained at the logging site back into the community's daily life. The company is moving forward with a plan to use dried chips to generate heat and electricity at the Kita Iwate Resource Recycling Center, which will be supplied to town-operated hot spring facilities and welfare facilities. In addition, plans are underway to build a new pellet plant, and sales of pellet stoves for home use have begun.

In addition, to encourage young people to settle in the area, the company is building and selling "child-rearing houses" made of 100% Iwate Prefecture timber. Plans are also underway to renovate a former JR facility to create dormitories and guesthouses for students studying in the mountain villages, thus materializing "a community where people can continue to live. In addition, an exchange center has been established to introduce wood energy and local timber. It also provides a place where residents can get involved with the forest through woodworking workshops and stove experiences.

President Shibata said, "If the project is completed only in the mountains, there will be no way out. It is important to create a cycle of burning, living, and supporting in the community.

Shibata Sangyo's efforts have demonstrated a new forestry model that integrates “production” and "community" through the use of data. The results of the forestry DX have spilled over into the creation of a regional circulation system, forming a "regional ecosystem" involving energy, housing, and education.

I want to make this town a place where children can “choose” to live,“ says President Shibata. President Shibata's words symbolize not just DX, but ”forestry that nurtures people and communities.

Reference Links

Shibata Sangyo Co.