Producing fuel and chemical products from wood and other materials: Key points for commercialization learned from leading overseas companies

Updated by Taro Kamagata on December 26, 2025, 9:16 PM JST

Taro KAMAGATA

(Platinum Initiative Network, Inc.

After graduating from Keio University with a degree in economics in 1982, he joined Toppan Printing Co. In 1988, he moved to Mitsubishi Research Institute, where he was in charge of urban and regional management and public-private partnerships (PPP, PFI, etc.). He later became an executive officer and served as Director of the Regional Management Research Division, Director of the Platinum Society Research Division, and Managing Executive Officer and General Manager of the Research and Development Division, etc. He was seconded to Mitsubishi Research Institute DCS as Senior Managing Director in 2018, retired as an officer of Mitsubishi Research Institute in 2021, and became an advisor to Platinum Initiative Network in 2022. Leader of the Secretariat of the Platinum Forest Industry Initiative.

last timePreviously, we introduced biomass conversion technologies. This time, we will introduce the initiatives of companies that are utilizing these conversion technologies and moving toward practical application.

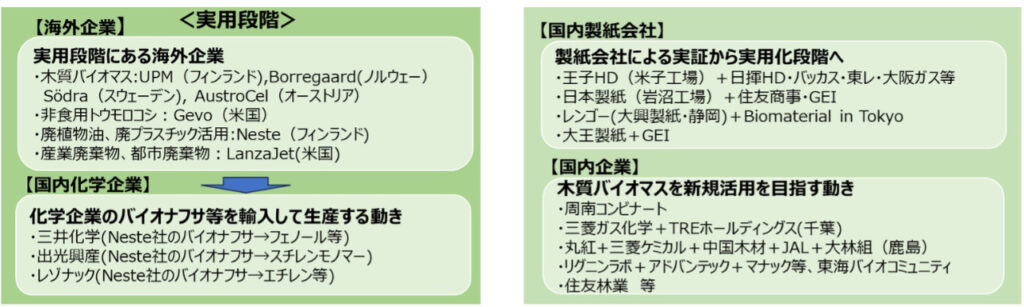

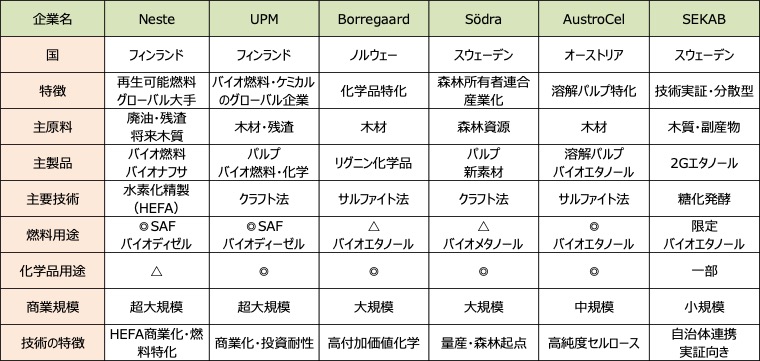

Overseas, several companies are already producing bio-naphtha and other chemical feedstocks at a practical level using woody biomass alongside biomass resources such as waste vegetable oil and non-edible corn. Representative examples include Nordic companies such as Finland's Neste and UPM, Norway's Borregaard, and Sweden's Södra.

Meanwhile, in Japan, there is a growing movement to produce chemical products such as phenol using imported bio-naphtha and other materials, but cases of commercial-level production and sales of chemical raw materials from domestic biomass resources are still limited.

The paper industry is showing the most promising progress toward practical implementation domestically. Against a backdrop of declining paper demand, companies are leveraging existing paper mill plants and raw material supply chains—such as wood chips—to pursue biorefinery projects, advancing them to the demonstration stage.

In contrast, projects to produce chemical feedstocks and biofuels from domestic woody biomass at new plants are largely still in the study and research phase at this time, with full-scale operations yet to begin.

Companies commercially producing chemical feedstocks such as biofuels and bio-naphtha from biomass and waste are common in Europe and North America. However, companies commercially operating using woody biomass feedstocks are limited to those transitioning from existing businesses like paper and pulp in Northern Europe and Austria. Each company leverages distinct technologies and feedstocks (including residues) to develop unique business models.

●Neste (Finland)

Neste is a world-leading producer of sustainable aviation fuel (SAF), renewable diesel fuel, and renewable feedstock solutions for various polymers and chemicals. Using feedstocks such as used cooking oil, animal fat residues, and vegetable oil processing residues, it employs a unique manufacturing process distinct from crude oil refining (including feedstock pretreatment, deoxygenation via hydrogenation, and molecular structure conversion). A key feature is its large-scale production of finished fuels (including naphtha).

Within Japan, several chemical companies have begun initiatives to produce and sell chemical feedstocks utilizing bio-naphtha produced by Neste.

●UPM (Finland)

UPM is a global leader in the forest and bio-based industries, representing Finland. It is transitioning its business away from being a pulp and paper company toward the production of biofuels, biochemicals, and advanced materials. Leveraging its own forests, UPM operates a vertically integrated business spanning pulp to biofuels and biochemicals—a globally rare capability.

We process and refine byproducts obtained from the kraft pulp process (such as lignin, fatty acid/rosin mixed oil) to produce biodiesel (BioVerno), bio-naphtha (chemical feedstock), and gas (plant energy). BioVerno is suitable for 100% diesel replacement (B100) and is increasingly used in buses and trucks across Europe.

Additionally, we are pursuing an Alcohol-to-Jet business that separates forest resources into components, produces ethanol through saccharification and fermentation, and then converts it into Sustainable Aviation Fuel (SAF). We are also advancing the development of sugar-derived monoethylene glycol/monopropylene glycol and high-performance resin raw materials derived from lignin.

●Borregaard (Norway)

Borregaard is a company that has transformed its business structure since the 1960s, shifting away from a focus on pulp and paper manufacturing to produce biochemicals and high-value-added biomaterials derived from wood (wood-based resources).

We separate, purify, and convert cellulose, lignin, and sugars derived from wood into high-value-added specialty chemicals, biochemicals, and materials. Our business operates across three segments: "Lignin-based Biopolymers/Vanillin," "Specialty Cellulose Products," and "Precision Chemicals, Bioethanol, and Pharmaceuticals based on Cellulose and Sugars." We are particularly distinguished by our diverse range of lignin-derived products, which are carving out unique markets.

●Södra (Sweden)

Södra is Sweden's largest forest owner cooperative and an international forestry group, with over 50,000 forest owners participating as members. It is a business entity with an integrated product portfolio ranging from raw timber to wood, pulp, biofuels, bioproducts, and building materials.

We have established an integrated forestry value chain spanning raw material supply to manufacturing and sales. Starting with the production of construction and structural lumber, our total annual pulp production capacity reaches millions of tons, manufacturing kraft pulp (paper: for corrugated cardboard) and dissolving pulp (for textile applications, etc.). Furthermore, going beyond being a mere wood and pulp manufacturer, we utilize byproducts from the pulp process to also produce bio-based chemicals and fuel feedstocks. We operate a biorefinery-type business that separates and recovers lignin, tall oil, methanol, and other substances from black liquor generated in the kraft pulp process, highly utilizing them as fuels and chemical feedstocks. This establishes a circular industrial model centered on cellulose products while multi-stage deploying by-products into the energy and chemical sectors.

●AustroCel (Austria)

AustroCel is one of Europe's leading biorefinery companies utilizing woody biomass. It operates a mill founded in 1890 with a dissolving pulp production capacity of up to 160,000 tons per year. In 2021, it began producing bioethanol using byproducts, with an annual capacity of 30 to 35 million liters. Additionally, it is developing new agricultural materials, such as biodegradable hydrogel water retention agents, utilizing lignin derived from dissolving pulp byproducts.

The company's green ethanol is price-competitive due to its near-zero raw material costs (utilization of pulp by-products), energy advantages including in-house power generation, and high external sales value of by-products (lignin). It is already being sold commercially and is being supplied to Austria's state-owned oil company.

●Sekab (Sweden)

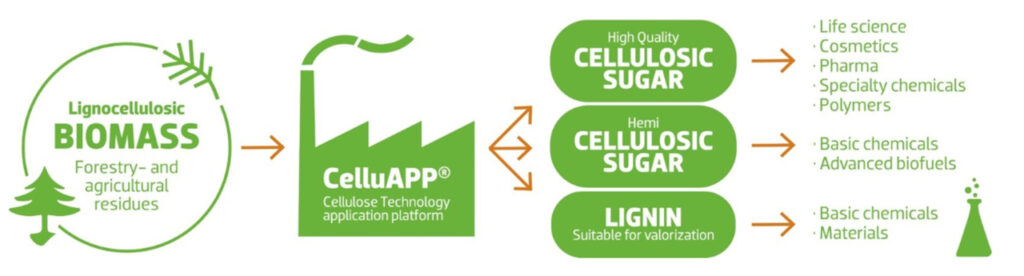

Sekab refines ethanol from biomass resources and produces various basic chemicals and chemical products. Ethanol has diverse applications, and the chemical plant produces bio-acetaldehyde, bio-ethyl acetate, and bio-acetic acid.

First-generation ethanol was produced from agricultural products such as sugarcane, grains, and corn. Currently, we are working on manufacturing products using woody biomass as feedstock for second-generation cellulosic ethanol.

(Platinum Concept Network Advisor, Taro Kamagata)