[Austria inspection report: Recommending high-quality forestry] Investment in forestry roads increases productivity; gravel is 40 centimeters thick, twice as thick as in Japan thick, twice as thick as in Japan

Updated by Yasunao Kobayashi on January 26, 2026, 8:15 PM JST

Yasuhisa KOBAYASHI

Alpha Forum, Inc.

President of Alpha Forum, Inc. and Steering Committee Member of the Platinum Forest Industry Initiative. Ltd. in 2001, taking advantage of the company's venture support program. In September 2023, he received the Wood Use System Research Association Award.

*Previous column is here.

[Austria Study Tour Report] Requirements for "High-Quality Forestry" Guided by the Balance of Culture, Environment, and Structure

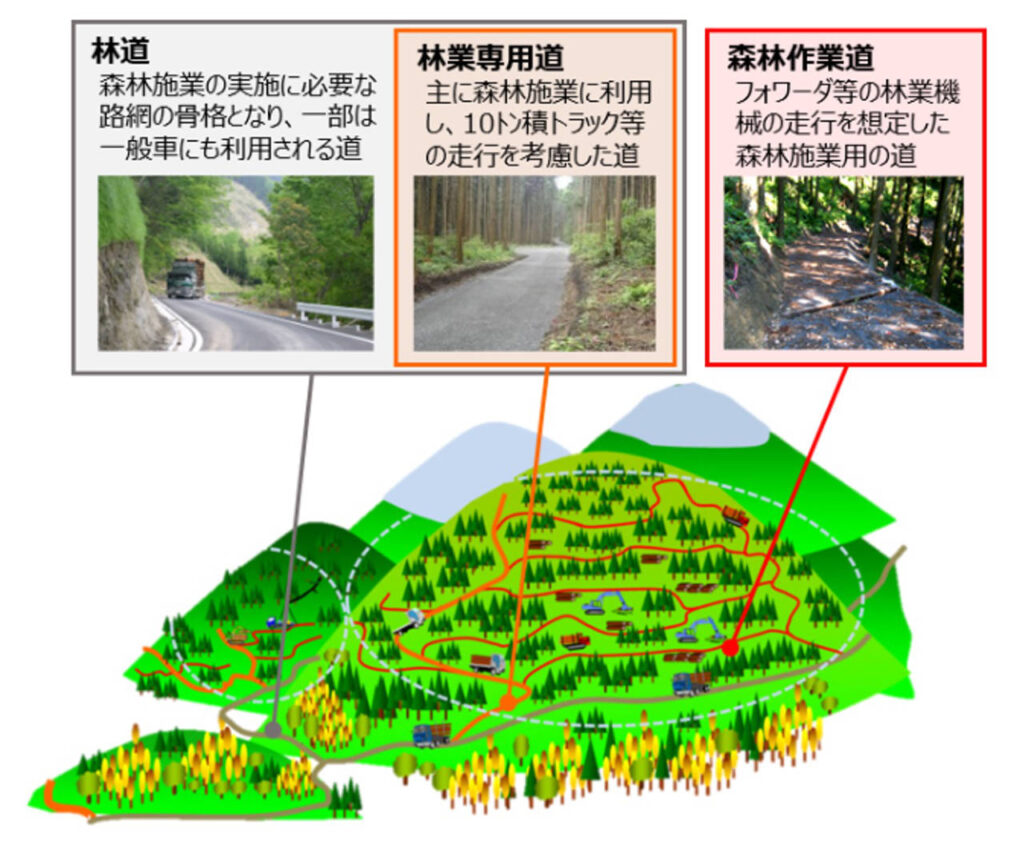

I would like to talk about "roads" necessary for forestry. There are three main types of forest roads. Forest roads" are used for everyday life and are accessible to ordinary vehicles, and people not involved in the forestry industry pass through them without even being aware of it. There are "forestry roads" that are intended for large vehicles used for forestry purposes. Since general vehicles are not allowed on these roads, it is unlikely that you will ever see them.

20 cm and 40 cm are the thicknesses of gravel for forestry roads. For more information on standards for forestry roads in Japan, please refer to the Forestry Agency's website. In Japan, the thickness of gravel on forestry roads is generally set at 20 cm. 40 cm is the thickness of gravel on forestry roads in the training forest in Pichl, Austria, which we visited on December 3, 2025. Gravel thicknesses twice as thick as those in Japan are normal in Austria.

This is due to the soil type of the mountain forests. The soil in Japan is "mud" and the soil in Austria is "rock," which is the surface layer of soil. The gravel layer becomes thicker by spreading and consolidating the gravel, and the director of Pichl told us, "Actually, you can't make a 40-centimeter layer of gravel just by cutting rocky soil (excavated soil and rocks generated when cutting a road), So, we have to bring in what we don't have. The road is intended to be a permanently usable forestry road.

The photo shows a dedicated forestry road in Austria Pichl's training forest with 40 cm of gravel. There was a light dusting of snow on the road, but the shape of the snow was also interesting to note. It has a so-called "kamaboko-shaped" cross-section. In order to prevent the flow of water from crossing the forestry road when it rains, a cut has been made on the mountain side and drainage pipes have been run under the road at appropriate intervals. The slope is gentle enough to allow trailers carrying materials (logs) to pass through without stress.

On the other hand, even in Japan, there are many cases where the surface layer is rock, but it is basically mud, which must be brought in from elsewhere to do gravel bedding. Mud can be easily scraped away with a backhoe, but if rocks are encountered, a backhoe will have no teeth, so a separate heavy equipment head to break up the rocks must be provided. Generally, when gravel is to be spread, it has to be brought in from other locations by dump truck or other means.

Which costs more, breaking rocks or scraping mud? As I see it, I think it is the cost of crushing the rock. If there is not enough gravel to crush the rock, it will cost more to bring it in, but first we should realize that a trailer full of logs can pass through.

Considering the fact that forestry roads quickly become rutted and slippery, and that trailers have to repair ruts and fearfully pass through them each time, "roads that trailers can easily pass through and continue to use should be established, even if the initial cost is high. We should cooperate with civil engineering and construction technology to conduct thorough research on cost reduction.

I hear people say, "That's not going to break even..." but I believe there is a lot of room for research and development.

In Japan, we hear "reasons why we can't do it" such as "laws and regulations," "lack of public budget," "no precedent in the past," "the person in charge has just been replaced," "it's just a goal (a statement)," and so on. As a result, when only half of the target was achieved, they blame other things or other people without any sense of apology. In the past, I once applied to a city and prefecture for a tower yarder to thin a row of broadleaf trees in order to collect various data, but was told, "There is no precedent for this, so please use it to clear out obstructions in the broadleaf trees..." I reluctantly agreed. The horizontal collection distance with the tower yarder hauler was extremely short.

The thinking is the opposite: in response to the need to produce 100 materials each year in the subject lands, we must ask ourselves, "What do we need to do to achieve our objective?" "We need to fell 0 cubic meters of trees each day," "How many round trips do the trailers need to make each day," "What are the measures (alternatives) in case heavy equipment fails," "We must negotiate the gray areas in the regulations," "We must proceed with the revision of the ordinance," and so on. What must be done to achieve the objectives? Where do we have to start? What needs to be done? Who will be responsible for dealing with it? And then actually start the work. This is backcasting.

In Austria, the work team has been asking the manufacturer of high-performance forestry equipment We have to ask the manufacturers of high-performance forestry machinery what they want and how far they are willing to go to meet it. As a result, several leading manufacturers of forestry machinery in the world have grown up.

In the forestry industry in Japan, it is common for heavy caterpillar machines called "forwarders" to go back and forth from the logging site to the mountain soil area where the trees are loaded onto trucks. Even if a 10-ton truck can enter the forestry road, only heavy equipment such as forwarders, harvesters, and grapples move through the work road for about 100 to 300 meters beyond that point. Harvesters, which are high-performance forestry machines, are also highly efficient and can do 50-60 cubic meters/day of felling (material production) work. The rate-limiting factor at any site is the forwarder. The forwarders are 4 to 7 tons per load, and the logs are loaded onto the forwarders, transported 200 meters by caterpillar, unloaded at the logging site, and returned again to the logging site. How many minutes would it really take for one round trip? If we consider loading and unloading, it would take 15 to 20 minutes per round trip, which is only 3 to 4 round trips per hour.... Shortening the forwarder distance as much as possible will lead to improved material production efficiency.

Although forwarders are sometimes used in Austria, the company considers it fundamental that trailers be able to lay down right next to the timber harvesting site with a tower yarda. Tower yarders can be very efficient depending on how they are used, and at the site we visited (guided by Conrad), the tower yarders are used for thinning at a rate of 12,000 cubic meters/year.

The moment you say, "Our country can't do this..." you should realize that you are declaring a loser. Take the money out of the discussion, sort out what is needed and where to start, and calculate the costs last. If the cost is too high and the business does not balance, then cost reduction measures should be considered. If the cost is still too high, we will consider cost reduction measures, and if the cost is still too high, we will consider how far we need to raise the efficiency of the work. (President, Alpha Forum, Inc.; Yasunao Kobayashi, Steering Committee Member, Platinum Forest Industry Initiative)