Manufacturing and public value starting from forests - Turning entire biomass basins into growth areas

Updated by Oji Holdings Corporation on June 24, 2025, 6:53 PM JST

Oji Holdings Corporation

Headquartered in Tokyo (Chuo-ku, Tokyo), Oji Holdings was founded in 1873. Oji Holdings' purpose is to nurture healthy forests, create products that utilize forest resources, and deliver them to society in order to move the world toward a future full of hope. Wood-based products derived from forest resources are expected to replace plastic films and fuels derived from fossil resources, as their raw materials are renewable. Properly managed forests contribute not only to carbon fixation, but also to flood mitigation, water source recharge (e.g., water purification), disaster prevention, biodiversity, human healing, health promotion, and other benefits.Official Site

The woody biomass business is expected to become a core industry for the next generation toward the realization of a sustainable society. We will talk with two members of Oji HD about the various resources, know-how, and technologies that a paper company with 150 years of history has cultivated.

Under the leadership of Hiroyuki Isono, who assumed the position of CEO in 2023, we held a series of internal discussions to determine what our strengths would be for the next 150 years. As a result, we decided to return to our original purpose (raison d'etre), which is to cultivate forests and provide society with products that make use of these resources, based on our long history in the paper manufacturing industry.

Takehito Okutani, Chief Innovation Officer of the Oji Group and General Manager of the Innovation Promotion Division, which is responsible for the Group's research and development, talks about the woody biomass business.

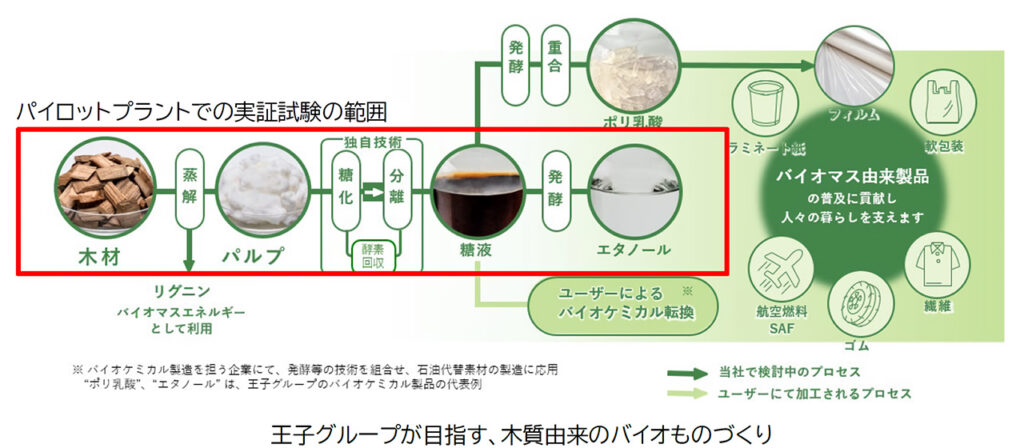

The basis of our biomass business is, first, the 7 million tons of lumber we procure annually from forests around the world on a stable basis under sustainable and sound forest management. And secondly, the technology to process large quantities of this biomass material into pulp, an alternative raw material to fossil resources. And thirdly, I think we have been able to build a recycling system without waste for some time now, thanks to biomass energy from the black liquor (lignin) we extract during the manufacturing process.

As Mr. Okutani said, the company's "bio manufacturing business" has the advantage of being able to "do anything" with the high-quality pulp produced daily in its core paper manufacturing business. At this juncture, the "bio manufacturing revolution" to create biofuels such as SAF (Sustainable Aviation Fuel), recyclable biomass plastics, and a wide range of bio-derived chemicals is underway, and in conjunction with the government's major policy to become carbon neutral by 2050, the group is also accelerating its activities. The company is also working on the development of a new business model that will be carbon neutral by 2050.

The three pillars of biomanufacturing are sugar solution derived from woody biomass, ethanol made from sugar solution, and polylactic acid. Sugar solution, produced by enzymatic treatment of pulp using a proprietary method, is expected to become a key material for various chemicals, and ethanol, produced by fermentation of sugar solution, is expected to replace SAF and similar petroleum-derived chemicals. Currently, we are working on establishing a system to provide samples to other companies that are sympathetic to the development of wood-derived bio-chemical materials. In the future, although it is only a concept, we hope to build a kind of "biomass complex" that can be supplied through a pipeline from our plant.

In addition to biofuels, bioethanol may be used as synthetic rubber (butadiene) to make biomass plastics and tires. In addition, polylactic acid, which is expected to account for nearly 40% of the 2 million tons of biomass plastic to be introduced annually by 2030 by the Ministry of the Environment, can be produced through lactic acid fermentation of sugar solution derived from woody biomass.

A pilot plant with a capacity of up to 3,000 tons and 1,000 kiloliters of sugar and ethanol per year, respectively, has been constructed at Oji Paper's Yonago Mill in Tottori Prefecture, and is currently undergoing demonstration operations. We have also succeeded in synthesizing up to 0.5 tons per year at a bench plant for polylactic acid at the Bio-Chemical Research Center in Edogawa-ku, Tokyo. As for sugar solution and ethanol, we will proceed with feasibility evaluations within the next two to three years, and plan to start up full-scale production facilities with a capacity of 200,000 tons/year for sugar solution and 100,000 kL/year for ethanol by 2030."

In addition, as a bio-manufacturing project involving other companies, an existing paper mill is being converted into a bio-manufacturing plant. There is also a movement to realize a competitive hub by integrating multiple industries around this plant.

NEDO*The six companies are JGC Corporation, Bacchus Bioinnovation, ENEOS Materials, Osaka Gas, Toray Industries, and Oji HD. Using Oji's woody biomass as a raw material, the plan is to build an eco-system that uses the power of microorganisms to create a variety of petroleum-substitute materials. Furthermore, since Oji Paper has existing assets such as a supply and distribution network for wood chips, pulp manufacturing processes, and a high level of wastewater treatment to reduce environmental impact, we plan to strengthen corporate collaboration with a focus on paper mills."

In addition to these major trends, promising resources are emerging in completely new technologies and materials derived from woody biomass. A representative example is "biomass resist for cutting-edge semiconductors," a revolutionary technology that uses biomass raw materials to produce photoresist, a photosensitive material used to form circuit patterns on semiconductors.

The "high resolution at the level of 8 nanometers is achieved in response to increasingly finer circuit patterns due to higher performance. PFAS, a raw material directly extracted from wood, is said to be harmful to the environment and human health.**It is expected to become a key technology in the semiconductor market, which is expected to expand further.

Originally, Oji HD's decision to shift to the biomass business was based in no small part on a sense of crisis over the global paper market, which has been shrinking year by year. However, Oji HD has taken a positive view of the situation, and in the midst of a new trend to utilize its accumulated papermaking technologies, know-how, and assets, the company is now taking a view of the industry from upstream to downstream on a scale never seen before.

New Energy and Industrial Technology Development Organization (NEDO)

Generic name for perfluoroalkyl compounds and polyfluoroalkyl compounds

I feel that our group has a great deal in common with the Platinum Forest Industry Initiative in terms of both the forests and the use of the forests. In particular, my department's mission is to commercialize the various values of forests beyond timber production, such as carbon neutrality, nature positivity, and the creation of a water environment and soil that nurtures living organisms, as well as the public benefit functions of forests that have not been recognized as having economic value.

says Hiromi Yamamoto, manager of the Oji Forest Revitalization Promotion Department in the Group Marketing Division of Oji Management Office Co.

In the 1930s, Ginjiro Fujiwara, then president and CEO of the company, stated that "those who use trees have an obligation to plant trees," and over the past 100 years, the company has cultivated the Oji Forest, a company-owned forest that covers a total area of approximately 635,000 hectares worldwide. The Oji Forest is characterized by the fact that it maintains and manages both production forests and environmental conservation forests in an integrated manner. About one-third of these forests are positioned as "environmental conservation forests" that focus on forest preservation activities. The economic value of the Oji Forest in Japan based on its multifaceted function is estimated to be 550 billion yen per year.

The economic value of forests in this "natural capital accounting era" is being reevaluated around the world, and is expected to cover a wide range of activities, including water source recharge, biodiversity conservation, sediment runoff and collapse prevention, atmospheric conservation, and health and recreation for local residents. In the future, the value of natural capital (stock) will also be considered.

In the context of the growing importance of economic growth within the so-called "planetary boundary" in terms of sustainability, we would like to propose the "Oji Model" as a global standard. As an attempt to achieve this, we are collaborating with Hokkaido University researchers on a project to visualize and restore the Oji Forest in Sarufutsu, Hokkaido, in terms of the five elements of CO2, biodiversity, soil, nutrition, and water. Specifically, we are studying the amount of carbon stored underground while encouraging the return and spawning of Itou, a rare fish; preventing the wetlands, including the peat layer, from drying out; and estimating the impact on the marine ecosystem, including the famous scallop from the supply of iron from the wetlands to the sea via the river.

The company also collaborates with overseas startups for biodiversity assessment, and utilizes advanced technologies and knowledge such as voice sensors, fixed-point cameras, drones, and environmental DNA for data collection. The data obtained is analyzed by AI to comprehensively evaluate biodiversity.

The connection and richness of forests, water, and oceans as stock will become increasingly valuable in terms of revitalizing regional economies and creating local communities. The Oji Group owns vast areas of company-owned forests throughout Japan, so we have rivers where everything from upstream to downstream flows into the ocean is Oji's company-owned forest land, making it possible to study the multifaceted effects of forests. I think this is one of our unique strengths.

Quiet but great expectations are now being pinned on efforts to regenerate nature and industry, starting with the Oji Forest.

The book of the same title as this web media, "Forest Circular Economy" (edited by Hiroshi Komiyama) was published by Heibonsha on August 5, 2025. The book proposes a redesign of the economy, institutions, and local communities based on the three pillars of biomass chemistry, wooden cities, and forestry innovation in the cycle of "cutting, using, planting, and nurturing" forests. This practical book provides a point of contact between concepts and examples for those involved in policy making, social implementation, and the creation of businesses that make use of local resources.

View on Amazon