Updated by "Forest Circular Economy" Editorial Board on July 04, 2025, 3:12 PM JST

Editorial Board, Forest Circular Economy

Forestcircularity-editor

We aim to realize "Vision 2050: Japan Shines, Forest Circular Economy" promoted by the Platinum Forest Industry Initiative. We will disseminate ideas and initiatives to promote biomass chemistry, realize woody and lumbery communities, and encourage innovation in the forestry industry in order to fully utilize forest resources to decarbonize the economy, strengthen economic security, and create local communities.

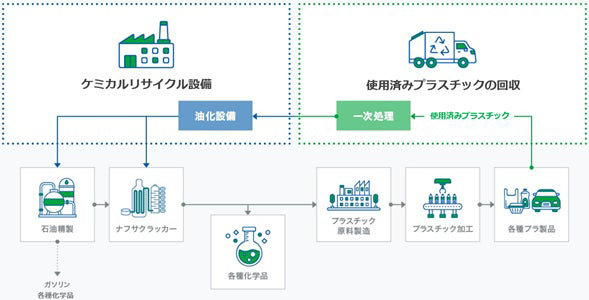

ENEOS and Mitsubishi Chemical Corporation have completed construction of a chemical recycling facility at Mitsubishi Chemical's Ibaraki Plant in Kamisu City, Ibaraki Prefecture, and held a completion ceremony on July 2. The new facility will accelerate the circular economy of plastics by setting up a system to produce recycled product oil from waste plastics in order to realize the conversion of plastics into oil.

At the new facility, used plastics procured from external sources will be chemically liquefied and converted to oil using the supercritical hydrothermal cracking technology of Mura Technology of the UK. This technology uses supercritical water at high temperature and high pressure as a solvent to break down plastics. The water in which the plastic is dissolved inhibits the recombination of the product oil and produces recycled product oil.

The produced oil will be utilized as feedstock for ENEOS and Mitsubishi Chemical's existing oil refining equipment and naphtha crackers, and will be reprocessed into petroleum products and various chemicals and plastics. This will realize chemical recycling that converts waste into new valuable resources.

Such technological efforts also have implications for the way materials, including biomass resources, are recycled. For example, in wood-derived materials such as cellulosic plastics, which have been the focus of attention in recent years, there is a need for progress in product design and processing technology with a view to recycling after use.

The development of chemical recycling technology, as typified by plastic oilification, is not limited to petroleum-derived materials, but will be helpful in considering the cyclical use of various waste materials in the future. In the field of forest circular economy, it will become increasingly important to consider recycling technologies that match the characteristics of materials for sustainable resource use.