Updated by Editorial Department of "Forest Circular Economy" on July 03, 2025, 10:00 AM JST

Editorial Board, Forest Circular Economy

Forestcircularity-editor

We aim to realize "Vision 2050: Japan Shines, Forest Circular Economy" promoted by the Platinum Forest Industry Initiative. We will disseminate ideas and initiatives to promote biomass chemistry, realize woody and lumbery communities, and encourage innovation in the forestry industry in order to fully utilize forest resources to decarbonize the economy, strengthen economic security, and create local communities.

TOYO announced on July 2 that it has developed the MRF-Z Neo(TM), a reactor for small-scale plants optimized for green methanol production. This technology, which applies the company's knowledge cultivated in large-scale plants, has the potential to open new avenues for energy production in regions dotted with forest residues and other biomass resources. As social demands for decarbonization grow stronger, this technology is likely to play a role in helping to realize a decentralized production model that makes use of local resources.

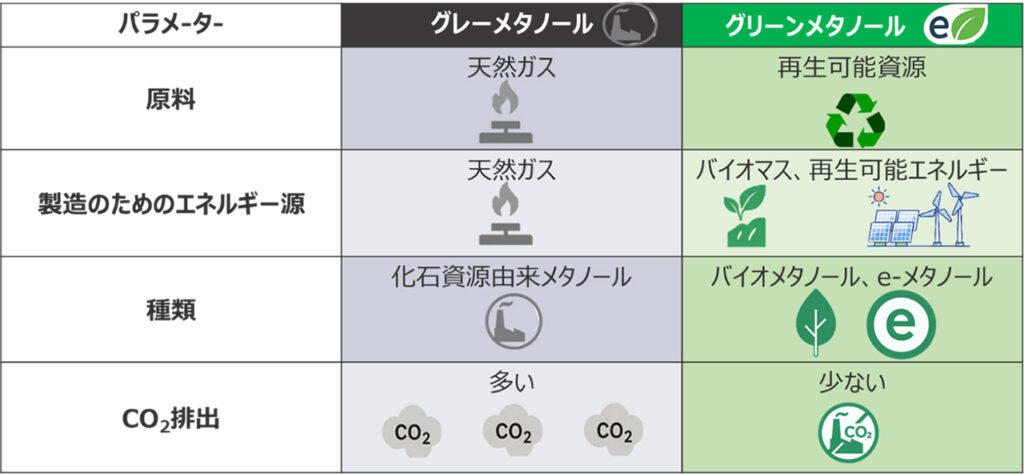

Green methanol is methanol produced from biomass resources such as agricultural residues and forestry waste, as well as hydrogen and CO2 derived from renewable energy sources, and is a next-generation energy source for which demand is expected to increase as a marine fuel and raw material for chemicals. However, the biomass resources and renewable energies used as raw materials are geographically dispersed. As a result, efficient production in conventional large-scale centralized plants has been a challenge. The fact that more than 97% of the world's renewable energy power plants are small-scale (less than 100 MW) also suggests the need for small-scale plants.

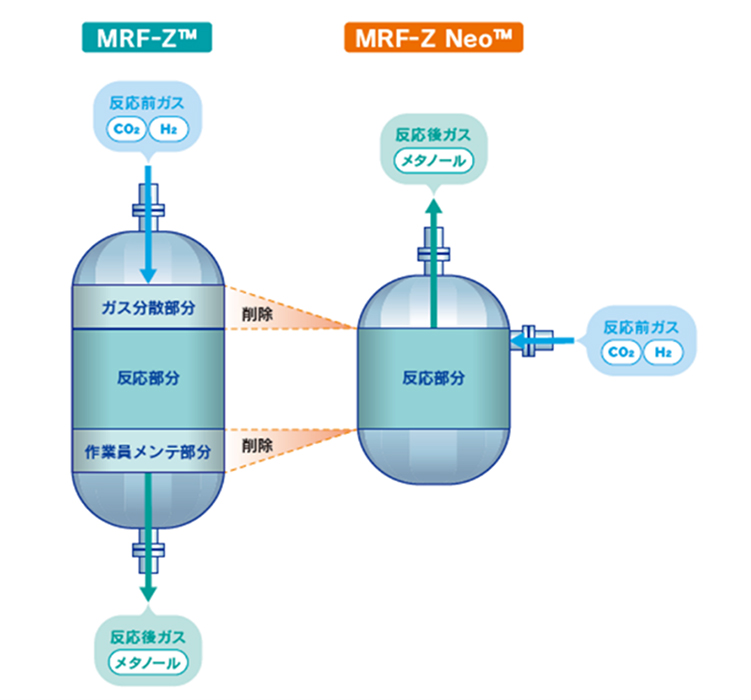

Against this backdrop, the company took the approach of optimizing the MRF-Z(TM), a large, highly efficient methanol reactor with a proven track record in large-scale plants, for smaller-scale applications. The newly developed MRF-Z Neo inherits the basic design that optimizes ideal temperature control and gas flow, which are the strengths of the company's technology. As a result, high reaction efficiency is maintained even in a small size.

The structure of a conventional large reactor was fundamentally revised to remove spaces for maintenance and other features that would be unnecessary in a small-scale plant. This bold design change has resulted in both a significant downsizing of the equipment and a cost reduction of up to approximately 401 TP3T compared to a simple downsizing of conventional technology.

The greatest significance of this technology is that it enables "decentralized production" utilizing the resources of each region. This is especially significant for regions with abundant forest resources. Biomass resources such as forest residues and lumber scraps, which have been difficult to utilize in the past, can be converted into high-value-added green methanol within the region.

The company is considering offering not only the newly developed "MRF-Z Neo" alone, but also a total solution combining its proprietary e-methanol production technology, energy-saving distillation system, and digital solutions to cope with fluctuations in renewable energy. By providing comprehensive support from the production to utilization of green methanol, rather than merely developing equipment, the company intends to accelerate the early implementation of green methanol in society and contribute to the realization of a decarbonized society.