The key to producing homogeneous polymeric materials from lignin is an interdisciplinary approach combining chemistry and biology

Updated by Kazunori Sonoki on August 18, 2025, 6:04 PM JST

Tomonori SONOKI

Hirosaki University

Associate Professor, Faculty of Agriculture and Life Sciences, Hirosaki University / Specialized in applied microbiology. He is working on the development of microbial functions for the production of homogeneous materials from lignin. He is promoting the realization of this through an interdisciplinary approach in which chemical degradation of lignin, fermentation production, and polymer synthesis are linked.

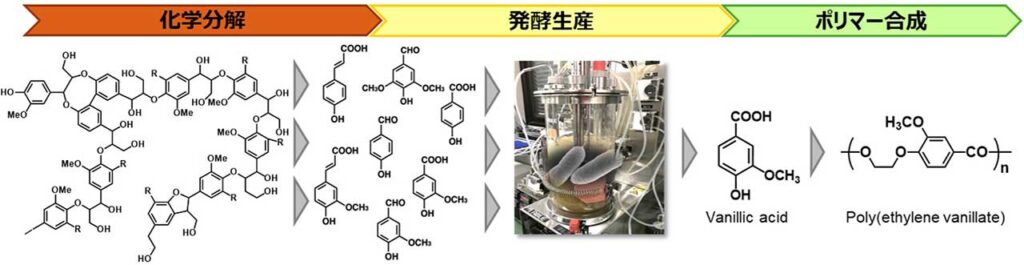

Lignin, along with cellulose, is a major component of woody and herbaceous biomass, but its non-regular and heterogeneous chemical structure is a barrier to its widespread use as a material (seeArticle on Forest Circular Economy on July 25for more information). One approach to overcome this heterogeneity and produce homogeneous materials from lignin is to once low molecular weight lignin and selectively extract specific useful compounds. However, since the low molecular weight process produces a mixture of various aromatic compounds with similar chemical properties, it is not easy to efficiently separate and recover only specific compounds and use them as synthetic raw materials for homogeneous materials.

In nature, there is a group of microorganisms that have acquired the ability to utilize and multiply such diverse aromatic compounds derived from lignin during the course of evolution. In the early 2000s, a concept was proposed from Japan to the world to convert and aggregate the mixture of aromatic compounds produced by the low molecular weight of lignin into specific compounds by utilizing the metabolic capacity of such microorganisms (*For details, seeForest Circular Economy article on August 4for more information). The use of microbial metabolism is now being addressed worldwide as an effective approach to the production of useful substances from lignin.

The method by which lignin is reduced to low molecular weight is extremely important in the production of useful substances utilizing microbial metabolism. Technology is required to enable microorganisms to take up lignin-derived compounds into their cells and efficiently break them down to a low molecular weight that can be metabolized. The major pulping processes currently industrialized (kraft and sulfite steaming) contain some compounds that can be used by microorganisms for growth, but the proportion is low and the compounds produced are diverse.

Since these processes have been developed for the purpose of "removing lignin," they cannot be applied to fermentation as is. Therefore, there is a need to improve or develop new low-molecular-weight technologies that are more compatible with microbial metabolism and "utilize lignin. For this purpose, it is important to conduct research and development while verifying the compatibility between the characteristics of degradation products and the metabolic capacity of microorganisms. Furthermore, minor compounds that may be present in the fermentation products may interfere with the polymer synthesis process in the subsequent stages. Therefore, it is important that R&D groups involved in chemical degradation × fermentation production × polymer synthesis work closely together to develop the technology.

Through such collaborative efforts, we have succeeded for the first time in the world in producing poly(ethylene vanillate), a kind of engineering plastic, from lignin (*).Hirosaki University, Nagaoka University of Technology and Obihiro University of Agriculture and Veterinary Medicine Joint Press Release). Aromatic compounds are known to impart excellent thermal stability and rigidity to polymers, and lignin, a natural aromatic polymer produced by plants, is a promising sustainable source of these compounds.

We are also working to develop technologies for the fermentation production of key compounds (such as 4-hydroxybenzoic acid and cis,cis-muconic acid) from lignin-derived aromatic compounds that can replace polymer materials conventionally produced from petroleum. These efforts, which can be materialized through an interdisciplinary approach that goes far beyond the conventional framework, are the key to overcoming barriers to lignin utilization and achieving homogeneous material production from lignin.

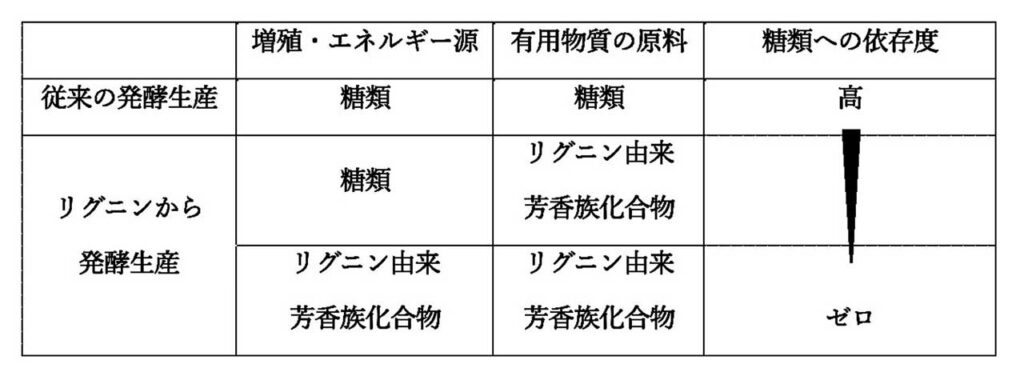

Fermentation production requires a source of growth and energy for the microbial strains used and a source of useful substances produced. In many fermentations, sugars (e.g., glucose) obtained by hydrolyzing polysaccharides (e.g., starch, cellulose) are used for both of these purposes. On the other hand, in the fermentation production of useful substances such as polymers from lignin, the reliance on sugars, which have been widely used in conventional fermentation, can be reduced because lignin is the raw material for the useful substances.

Furthermore, by utilizing species that have acquired the metabolism to utilize lignin-derived aromatic compounds as a source of growth and energy during evolution (Sphingobium lignivorans strain SYK-6, Pseudomonas putida strain KT2440, Pseudomonas sp. strain NGC7, etc. ), it is possible to create a sugar-free fermentation technology in which lignin-derived aromatic compounds provide all the carbon sources needed for growth, energy, and raw materials for material production. We are the first in the world to propose this concept, and we have developed a fermentation technology in which aromatic compounds produced by chemical treatment of lignin and biomass are used as raw materials for useful substances such as cis,cis-muconic acid, 4-hydroxybenzoic acid, and vanillic acid, as well as for microbial growth and as an energy source. The company is also developing a fermentation technology that does not use any sugars. (Associate Professor Kazunori Sonoki, Faculty of Agriculture and Life Science, Hirosaki University)