Updated by "Forest Circular Economy" Editorial Board on January 30, 2026, 11:19 AM JST

Editorial Board, Forest Circular Economy

Forestcircularity-editor

We aim to realize "Vision 2050: Japan Shines, Forest Circular Economy" promoted by the Platinum Forest Industry Initiative. We will disseminate ideas and initiatives to promote biomass chemistry, realize woody and lumbery communities, and encourage innovation in the forestry industry in order to fully utilize forest resources to decarbonize the economy, strengthen economic security, and create local communities.

*Click here for the first part.

The Okayama Model": Transforming Japan into a Nation Self-Sufficient in Resources and Urban Wood Construction, Challenged by Industry, Government, and Academia [Report on the Symposium on Forest Circular Economy, Part 1

The panel discussion in the latter half of the symposium featured Okayama-based practitioners from the forestry (upstream), lumbering and processing (midstream), construction (downstream), and government and consulting sectors. How do they translate their high aspirations into concrete businesses and local economic cycles? The discussion was rich in suggestions on how to resolve issues on the ground, as well as advanced case studies.

At the beginning of the discussion, moderator Taro Kamagata (Advisor to Platinum Initiative Network) presented the importance of three pillars and their collaboration to realize a circular forest economy: development of wooden cities, utilization of woody biomass, and innovation in the forestry industry.

Kentaro Kubota, president of Life Design Kabaya, which has held the top share of the detached house market in Okayama Prefecture for nine consecutive years, introduced the company's advanced initiatives as a "wooden general contractor. The company is actively expanding not only into the residential sector, but also into the nonresidential sector, including the research and development of the LC-core construction method, a fusion of the CLT construction method and wood-frame construction method, which began 10 years ago.

Meanwhile, the CLT Hybrid Construction Method, which introduces CLT load-bearing walls into the mainstay wooden frame construction method in the housing sector, received the Good Design Award and the Wood Design Award for its efforts to build a supply chain of prefectural lumber. Full-scale shaking table tests have demonstrated its earthquake resistance performance, with extremely little damage and displacement of only 4 cm, even after 70 seismic shocks, including a severe magnitude 7 earthquake. Mr. Kubota said, "We are proud that our house is the most earthquake-resistant house in Japan. We are confident that our house is strong enough to be used as an evacuation shelter.

In addition to the hardware, the company also focuses on education to deepen understanding of forests. Through a unique training program in which employees spend two years growing seedlings and actually participate in tree planting, the company has established a system in which employees learn about the connection between home building and forests as if it were their own personal business. Furthermore, in April 2025, the company will open a showroom "Structure Lab." to communicate the appeal of CLT, and is expanding customer support by presenting innovative designs. The company has set a goal of using 10,000 cubic meters of prefectural lumber in five years, which it has achieved in just three years, and is strongly leading the way in expanding the use of lumber from Okayama Prefecture and realizing a circular forest economy.

Koichiro Nakajima, President of Meiken Kogyo, who has played a pioneering role in the spread of CLT, explained the importance of breaking through fire resistance regulations and other "barriers. The company's CLT buildings not only boast extremely high earthquake resistance, with no damage sustained in a seismic intensity 7 vibration test, but also have such excellent thermal insulation and energy-saving performance that residents have reported a 40% reduction in their electricity bills. However, most wooden mid-rise and high-rise buildings must be covered with plasterboard to ensure fire resistance, a process that requires more labor and cost than the assembly of the structure, and involves heavy labor and danger on site.

To solve this problem, the company has been collaborating with Okayama University for more than five years to establish a "pure wood fireproof structure" that utilizes the difference in combustion temperature between different species of trees. He expressed his hope that the realization of showing wood without covering will dramatically change the urban landscape and significantly shorten the construction period.

He also expressed his view that, against the backdrop of Japan's income level and future social structure, it is essential to provide high-quality, long-lasting, low energy-loss wooden rental housing. He also mentioned concrete challenges to open a "windfall" in the stagnant industry, such as the development of new lumber manufacturing technology that could dramatically improve yields and compete with plywood.

Kosuke Shigehisa of C-Cube Consulting presented challenges and solutions for realizing wooden cities from his perspective as a member of the Chugin Financial Group, which supports regional development and the promotion of the forest industry. Through interviews with construction companies, Mr. Shigehisa analyzed that "cost" is the biggest reason why clients avoid wooden construction, and suggested the importance of quantitatively visualizing and communicating "value other than cost" in order to break through this barrier.

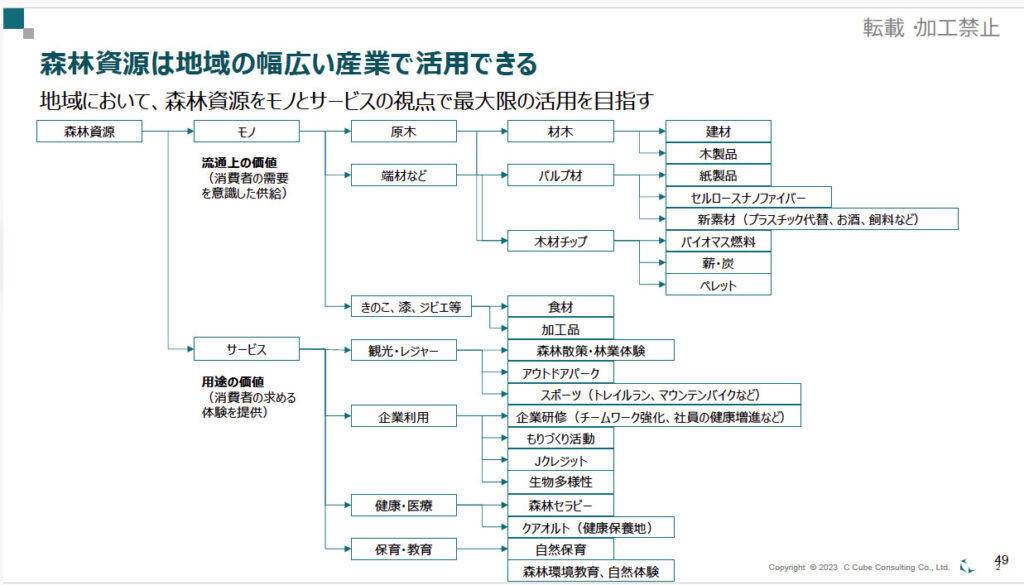

Specifically, the following three points are listed as "value. First is "value as living and living space," such as improved sleep, relaxation, and concentration. Second is the quantification of "decarbonization advantages," including lower CO2 emissions during transportation when compared to imported timber, which he pointed out is a powerful motivator, especially for companies that are required to disclose emissions. And third is the increase in "asset value," such as maintaining asset values equivalent to those of non-wooden buildings and the increase in rents and land prices due to the conversion to wood construction. In addition to the sale of "goods" in the form of timber, he also stated that the development of "services" such as J-credits and corporate reforestation, as well as the establishment of a cascade use system in which all the logs are used up, are essential for industrialization.

Mr. Shigehisa emphasized that there are still strong players in the northern part of Okayama Prefecture who are responsible for everything from logging to processing. He stated that Okayama, with its proximity to the large-scale demand centers of Okayama City and Kurashiki City, and the potential for biomass chemical use in industrial complexes, "is the best place to realize a circular forest economy," and expressed strong expectations for the realization of such an economy.

From the midstream perspective, which is responsible for the processing and distribution of lumber, the focus is on how to use up forest resources without waste. Mr. Yoshihiko Tahara, Managing Director of Insho Forestry, spoke about the enormous potential of Japan's forest resources, emphasizing that Japan ranks third in the world in terms of forest coverage and eighth in terms of the area of planted forests held, and that it has an abundance of mature resources that can be used at any time. In order to make effective use of forest resources, the company has established a vertically integrated system that handles everything from logging in the mountains to lumbering, pre-cutting, and housing construction. This allows the company to directly feed back the needs of the construction site to the sawing and logging processes to improve yields and reduce intermediate margins, thereby increasing the cost competitiveness of domestic timber.

In terms of technological innovation, the company has introduced Austrian-made tower yarders and large wheel loaders to cope with Japan's steep terrain, and is promoting productivity improvement through mechanization. In addition, the company introduced a case study of a 30% increase in logging output by dividing the process of road building, logging, and hauling out, which had previously been carried out by the same team, and by improving the process by having a separate team prepare the road network in advance.

In addition, for cypress, which is one of Okayama's strengths, the company is not limiting its use to conventional post lumber, but is also developing its value as a beam and girder (horizontal material) and conducting research on its strength. Mr. Tahara noted that the "cut, use, plant" cycle is essential for maintaining healthy forests, and pointed out the importance of a stable supply of seedlings for reforestation, the training of wooden architects who can handle non-housing construction, and the improvement of social literacy through tree education as future issues.

Mr. Nakajima of Meiken Kogyo introduced the case of the Maniwa Biomass Power Plant, which utilizes even bark as fuel, which was once treated as industrial waste. This project is operated with community-wide investment, and has been paying 12% dividends for 10 years on a capital of approximately 300 million yen. This is attracting attention as a successful example of regional energy self-sufficiency and economic circulation.

Despite the abundance of resources, serious problems remain in the upstream sites. Noboru Ota, Mayor of Maniwa City, pointed out that although cypress and other planted forests, which account for 75% of the city's forests, have reached their main cutting stage after 46 to 50 years, reforestation has stagnated. The main reasons for this are the industry structure, which is characterized by low timber prices that have worsened profitability, serious feeding damage by deer that cannot be caught up with even if 1,500 deer are exterminated annually, and high prices due to the monopolistic supply system for saplings.

Mr. Ota expressed concern about Japan's energy self-sufficiency rate of 11% and food self-sufficiency rate (on a calorie basis), which has fallen to 38%, and asserted that "Japan has no future unless it increases its energy and food self-sufficiency rates. Based on the fact that Maniwa City as a whole has achieved 85% energy self-sufficiency and 63% electricity self-sufficiency, he emphasized the creation of regional benefits through further "local production for local consumption" of electricity.

In particular, the Maniwa Biomass Power Plant has become the core of the local economy. The company has established a system to "turn what had been thrown away into profit and return it to the mountains" by returning a cumulative total of approximately 400 million yen over the past 10 years to forest owners who bring in unused wood such as branches and leaves to be used as fuel.

As a vision for the future, the company has set up a system to contribute to corporate management by supplying inexpensive electricity to local lumber mills and the challenge of chemical use of forest resources (conversion to chemical raw materials). Furthermore, in order to solve the shortage of human resources specializing in structural calculations, which has hindered the spread of wood construction, the company is focusing on human resource development through joint research at Okayama University's Maniwa Satellite Campus, and is also working to implement the "Okayama Model" through industry-government-academia collaboration.

Mr. Yoshihiro Miyake, Director of the Forestry Policy Division of the Agriculture, Forestry, and Fisheries Department of Okayama Prefecture, explained the "Okayama Forest and Forestry Vision" for the year 2050. The vision calls for the introduction of high-performance forestry machinery and intensification of forestry operations in planted forests that are suitable for forestry to develop highly profitable forestry operations, while forests deep in the mountains that are not suitable for forestry are to be converted to "mixed forests" with low management costs to fulfill multifaceted functions such as water source recharge and sediment runoff prevention. By clearly demarcating planted forests in this way, the strategy aims to achieve both recycling of resources and a stable supply of timber for the future.

Mr. Miyake also presented statistical data showing that current lumber prices have slumped to about one-third of their peak around 1975. Although there was a temporary price increase around 2021 due to the "wood shock," he analyzed that this was only a very limited change over a long-term span of 50 years, causing a decline in the motivation of forestry management. In addition, he expressed concern about the future shortage of resources, as the current largest number of planted forests is about 60 years old, while the number of young planted forests, which will carry the next forestry cycle, is extremely small.

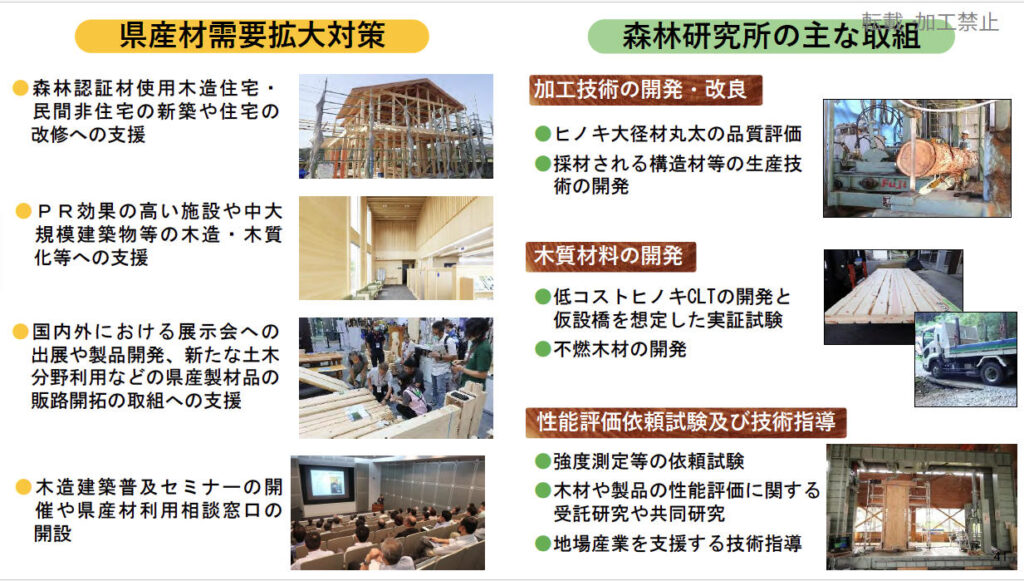

To address these issues, Miyake advocated the use of ICT and digital technology to save labor in forest management, support for overseas exports of prefectural lumber products, and the creation of new demand for lumber in the mid- to high-rise construction and non-housing sectors. Utilizing the results of research conducted by the Wood Processing Laboratory of the prefectural forestry research institute, he stressed the importance of establishing a system that ensures the return of profits to forest owners by enhancing the processing technology of sawmills to create new demand and added value. Ultimately, he explained that upstream, midstream, and downstream entities should work together to realize sustainable forest management through the forestry cycle of "logging, using, planting, and nurturing.

The "Okayama Forest Circular Economy Model" presented at this symposium is extremely important in that it is not simply a forestry promotion, but a "regional implementation strategy" that integrates the multi-level demand creation of construction and energy. The pure wood fire resistance research being conducted by Okayama University and digital reforms that focus on the entire supply chain have the potential to change the cost structure of wooden construction itself. These are just some of the ways to build the infrastructure that will allow the city to function as a "second forest. Full utilization of forest resources" through strong collaboration between industry, government, and academia will not only revitalize local economies, but also provide a powerful answer to the global challenge of decarbonization.

Reference Links

Okayama University] Okayama University Symposium "Toward the Realization of a Forest Circular Economy from Okayama" to be Held in Okayama, Japan | Okayama University National University Press Release

Life Design Kabaya spoke at the symposium "From Okayama: Toward the Realization of a Forest Circular Economy," hosted by Okayama University and co-hosted by Platinum Initiative Network, Inc! Toward the Realization of a Forest Circular Economy" hosted by Okayama University and co-sponsored by Platinum Initiative Network. | Press Release by Life Design Kabaya Co.