Updated by "Forest Circular Economy" Editorial Board on April 24, 2025, 10:24 AM JST

Editorial Board, Forest Circular Economy

Forestcircularity-editor

We aim to realize "Vision 2050: Japan Shines, Forest Circular Economy" promoted by the Platinum Forest Industry Initiative. We will disseminate ideas and initiatives to promote biomass chemistry, realize woody and lumbery communities, and encourage innovation in the forestry industry in order to fully utilize forest resources to decarbonize the economy, strengthen economic security, and create local communities.

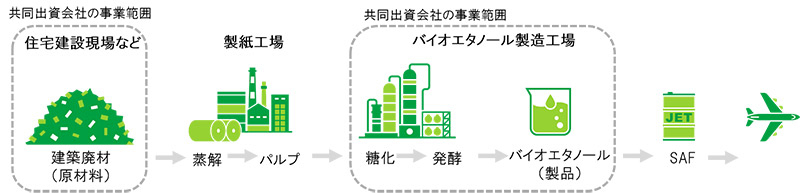

Sumitomo Forestry and Rengo announced on April 23rd that they have signed a basic agreement on wood-based bioethanol production. The project will produce bioethanol, a raw material for sustainable aviation fuel (SAF: Sustainable Aviation Fuel), from wood chips and other construction waste generated at housing construction sites. The company plans to find new value in construction waste, which has been difficult to utilize effectively, and to hasten the establishment of mass production technology for wood-based bioethanol, which is in growing demand as an alternative fuel to petroleum. The project is attracting attention as an important step toward resource recycling and decarbonization in Japan.

The core of the agreement lies in the fact that construction waste wood, which was often disposed of as waste in the past, is now regarded again as a valuable resource. Sumitomo Forestry's housing construction sites generate wood scraps and wood waste generated during processing. By using these as raw materials to produce bioethanol, the company is contributing to the realization of a recycling-oriented economy that both reduces waste and makes effective use of resources.

The bioethanol produced will be used as a raw material for SAF. The aviation industry is facing an urgent need to reduce CO2 emissions, and expectations for SAF are growing worldwide. SAF is produced from waste cooking oil, plants, wood waste, etc., and is said to significantly reduce CO2 emissions throughout its life cycle compared to conventional jet fuel.

Currently, the supply of SAF is still limited and much of it is dependent on imports. If bioethanol production using domestically generated construction waste as raw material gets off the ground, it will lead to domestic production and stable supply of SAF, and may accelerate decarbonization efforts in the Japanese aviation industry. From the perspective of energy security, fuel production using domestic resources is also of great significance.

The two companies aim to quickly establish mass production technology for wood-based bioethanol. The key to efficient production of ethanol from wood is technology to break down components such as cellulose into sugars. By combining Sumitomo Forestry's expertise in wood procurement and construction sites with Rengo's technology and knowledge accumulated through its paper manufacturing and other businesses, it is hoped that a practical mass production process can be developed.

Sumitomo Forestry has long been involved in the recycling of forest resources, and this agreement paves the way for the conversion of waste wood generated during housing construction to even higher value-added uses. By sending construction waste wood, which would previously have been incinerated or recycled at a lower price, to the high value-added market of SAF, it will also lead to the advancement of the economic cycle model of the forest industry as a whole.

As a major packaging materials manufacturer, Rengo has a proven track record in the use of recycled raw materials, and through this collaboration with Sumitomo Forestry, the company will take a new step forward in bioethanol production.

This collaboration is more than just the development of new energy production technologies. The collaboration between the housing/construction industry and the paper/energy-related industry, which have not had strong ties to each other until now, is based on the common goal of decarbonization, and suggests the possibility of reforming industrial structures and creating new business models in terms of adding new value to what used to be waste materials.