Linkage between forestry and lumber facilities and chemical plants is key to converting from oil to biomass

Updated by Kazuaki Hiraishi on May 08, 2025, 4:45 PM JST

Kazuaki HIRAISHI

(Platinum Initiative Network, Inc.

After graduating from the University of Tokyo in 1984 with a bachelor's degree in Civil Engineering, he joined Mitsubishi Research Institute, Inc. He served as Director of the Overseas Business Center, Director of the Policy and Economic Research Center, Deputy Director of the Policy and Public Affairs Division, Secretary General of the Asian Pipeline Study Group, Secretary General of the Northeast Asian Gas and Pipeline Forum, and Executive Vice President of MRI Research Associates, Inc. He has served as President of M.R.I. Research Associates, Inc. He specializes in infrastructure planning, transportation economics, and energy economics. D. in Engineering, Bachelor of Engineering (Construction).

New demand for woody biomass will arise from the conversion from petrochemical to biomass chemistry. In order to achieve carbon neutrality, fossil resources will be largely unutilizable as of 2050. This is true not only as fuels but also as raw materials. On the other hand, demand for plastics and other chemical products will remain strong. In addition to thorough recycling of chemical products, new production is expected to be shifted from petroleum-based raw materials to wood-based and other biomass-based raw materials (biomass crude oil). The Ministry of Economy, Trade and Industry (METI) is also aiming to achieve a "fuel shift" toward decarbonization of energy requirements in the chemical industry manufacturing process, as well as a "feedstock shift" from fossil resources to recycled or biomass feedstocks.

The government and industry organizations are actively promoting material and chemical recycling of waste plastics, and chemical companies are also actively developing related technologies. However, municipalities are still mainly engaged in thermal recycling, and the separate collection of waste plastics remains an issue. Future developments are expected to include the utilization of existing petrochemical complex facilities such as refineries and naphtha crackers, and the development of small plants close to the source of waste plastics, which will be transported in the form of cracked oil to petrochemical complexes on the waterfront.

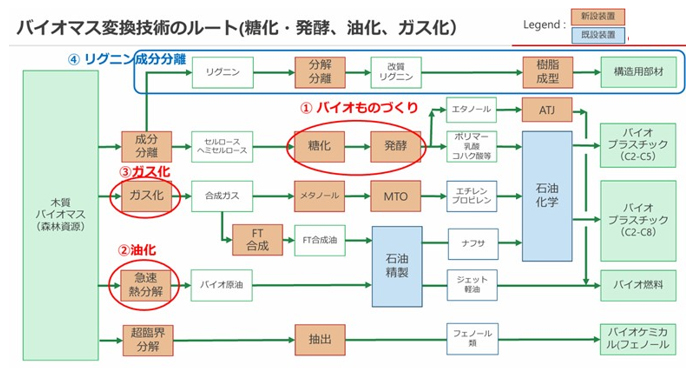

In converting biomass into chemicals and fuels, there are three routes: saccharification and fermentation, oilification, and gasification. Modified lignin is a technology that effectively utilizes woody biomass resources by separating cellulose and lignin components. These various conversion technologies are being actively studied by chemical companies, paper companies, trading companies, and venture companies. The development of these technologies for biomass resource utilization will likely be selected in consideration of cost and demand for chemical products. Pulp and paper mills have already begun to utilize surplus pulp resulting from declining paper demand to produce ethanol and chemical products at existing plants.

Biomass chemistry, which utilizes woody biomass and other resources, faces the challenge of securing biomass resources (especially domestic woody resources) compared to waste plastic recycling. Expanding the supply of forest resources and linking forestry and lumber facilities with chemical plants are key. In doing so, it is essential to reduce energy and costs during transportation. From the perspective of reducing transportation costs and CO2 emissions, it would be effective to separate components, saccharify and ferment woody biomass resources at a location as close as possible to their source, and transport them in liquid form, such as ethanol, to a petrochemical complex on the waterfront. This will also contribute to economic revitalization and employment expansion in forested areas.

Recycled and biomass-derived products are currently more costly than petroleum-derived products. It is necessary to foster user understanding of these products and to make concrete progress in market creation through tax credits, public procurement, subsidies, and carbon pricing by the government. It is also important for the public and private sectors to work together to secure low-cost green hydrogen, which is necessary to decarbonize the chemical industry. (Kazuaki Hiraishi, Executive Director, Platinum Initiative Network)

The book of the same title as this web media, "Forest Circular Economy" (edited by Hiroshi Komiyama) was published by Heibonsha on August 5, 2025. The book proposes a redesign of the economy, institutions, and local communities based on the three pillars of biomass chemistry, wooden cities, and forestry innovation in the cycle of "cutting, using, planting, and nurturing" forests. This practical book provides a point of contact between concepts and examples for those involved in policy making, social implementation, and the creation of businesses that make use of local resources.

View on Amazon