Updated by "Forest Circular Economy" Editorial Board on June 23, 2025, 5:53 PM JST

Editorial Board, Forest Circular Economy

Forestcircularity-editor

We aim to realize "Vision 2050: Japan Shines, Forest Circular Economy" promoted by the Platinum Forest Industry Initiative. We will disseminate ideas and initiatives to promote biomass chemistry, realize woody and lumbery communities, and encourage innovation in the forestry industry in order to fully utilize forest resources to decarbonize the economy, strengthen economic security, and create local communities.

The western region of Toyama Prefecture is surrounded by clean water and rich forests. In this region, a movement is underway to create a "new forest culture" that makes maximum use of the region's bounty and is nearly self-sufficient in resources and energy. The core of this movement is the construction of "local eco-systems," in which forest resources are recycled within the region and used as raw materials for wooden construction and energy supply. This initiative, which aims to break away from dependence on fossil resources and realize a decarbonized society, is more than just an environmental measure; it will also help revitalize the local economy and strengthen economic security. The editors of "Forest Circular Economy" report on the new circulation model promoted by the Western Toyama Prefecture Forest Utilization Project Study Council, in which local resources enrich the community.

In Himi City, where the sea and mountains are close together and the landscape is rich with satoyama, there is a brand of wood called "Himi Satoyama Cedar" that has been nurtured together with the nature of the region.

The satoyama in Himi faces the Sea of Japan and is humid, with moderate temperature differences and abundant snowfall in winter. These climatic conditions are extremely favorable for the growth of cedar trees. The soil, which is blessed with water throughout the year, supports the healthy growth of the cedar trees and helps them to grow soft and supple. Winter snow naturally thins out the branches and produces straight, knotless trunks.

The HIMILIYAMA cedar grown in this way has a beautiful gradation of pale reddish and white logs, and the gently rippling annual rings give a soft impression. When light hits the grain of the wood, gentle shadows are created, giving a sense of calmness to the space. In addition, the unique aroma of cedar contains relaxing ingredients such as cedrol, which brings a forest-bathing-like healing effect into the room.

New products are also being developed in collaboration with other industries. Products such as beer distilled from wood chips, ink made from tree bark, and aroma products that make you feel like you are taking a forest bath have been developed. In addition, the company is also promoting industry-academia collaboration, such as producing photo frames and key rings in cooperation with students of Toyama International University. The company also produces disposable chopsticks using wood from thinned forests, demonstrating its commitment to making full use of wood resources.

Himiriyama cedar also has excellent performance as a building material. Its softness and ease of processing make it easy to construct as a structural or interior material, and it is easy to use on site. In addition, traditional methods such as "leaf withering drying" and "moon-aged felling" are used to minimize wood distortion and cracking. This maintains high dimensional stability and durability.

In addition, since preservative and fire retardant treatments are possible through pressurized injection, Himi-satoyama cedar is increasingly being used in urban areas and public facilities. The Himi City Council Chambers, JR Toyama Station, Prefectural Rehabilitation Hospital, Toyama Prefectural Museum of Art, Toyama Prefectural Diet Building, and other facilities have all adopted our products, widely promoting the quality and aesthetics of Himiliyama cedar and contributing greatly to improving the brand image of the product.

Himi City, where the Himi Satoyama Cedars grow, is a diverse environment where mountains, rivers, and the sea are connected. Sound management of the mountains will eventually enrich the water in the rivers and have a positive impact on the fishing grounds in the sea. That is why protecting the forest also means protecting the natural environment of the entire region.

Takeshi Kishida, chairman of the Himi Satoyama Cedar Utilization Council, which promotes local production for local consumption and continues activities to increase the value of local timber, said, "The Council, which began in 2012 with the branding of Boca Cedar, is now focusing on projects to create a future for forests and people. We are connecting mountains, rivers, oceans, and people, and promoting lifelong tree care from birth to death. We see the Himi Satoyama Cedars not only as a material, but also as an entity that enriches the local culture and lifestyle, and we are aiming for World Agricultural Heritage certification with the cooperation of all Himi citizens," he says.

The Western Toyama Forest Utilization Project Study Council is working to strengthen the value chain from upstream (logging) to downstream (construction) in order to sustainably utilize local forest resources. The role of the "midstream" sector, which is responsible for adding value to lumber, is also extremely important. Woody Parts, headquartered in Takaoka City, is a symbolic example of this.

The company specializes in the pre-cutting and processing of structural timbers for wooden buildings. With "active use of domestic timber" as its management policy, the company uses its advanced design and processing technologies to add value to local timber, including cedar produced in Toyama Prefecture, and supplies it to a wide range of construction sites, from residences to public facilities and commercial buildings.

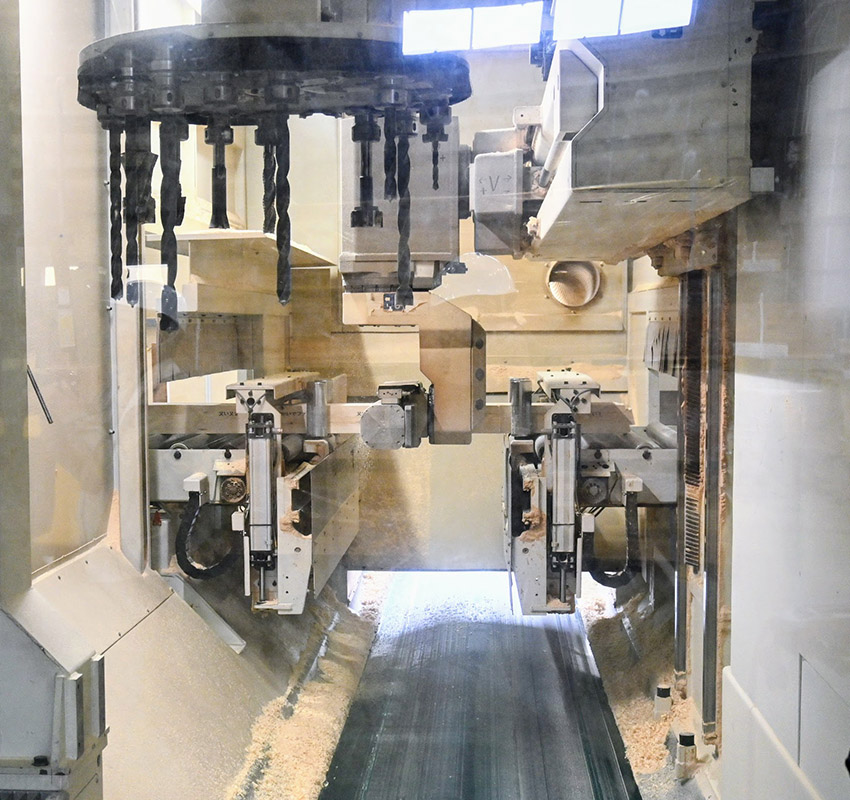

The key to this is the existence of an in-house factory that integrates design and manufacturing, where CAD-based structural design and CAM-based automated processing are seamlessly linked, and where accurate joint and finish processing is performed on a millimeter-by-millimeter basis based on blueprints for each piece of lumber. This allows for speedy and flexible response, and the plant has the capability of being a "full pre-cut plant" that handles a wide variety of construction methods, including conventional, hybrid, and metal-frame construction, as well as pre-cutting of shingles, plywood, and siding.

Advanced equipment supports the highly efficient production system. In particular, the 6-axis multi-purpose machining center has made it possible for one or two workers to perform complex machining tasks that were previously performed by several workers with carpentry skills, through program control. The spare manpower created by this system has been reallocated to other processes, thereby improving the productivity of the entire plant.

Further driving efficiency and manpower savings are the CAD/CAM linkage system and automatic wood feeding and discharging equipment. The system automatically generates machining data from design data, eliminating the risk of input errors and enabling highly accurate machining in a short time. Furthermore, the introduction of equipment that automatically supplies and discharges lumber to the processing machine has reduced the burden on workers and enabled the line to operate continuously.

The factory is organized and clean, with workers checking monitors as they work, and consistent control of everything from manufacturing to quality control. Large-scale pre-cut machines process structural timbers, including cedar from Toyama Prefecture, one after another.

The company can handle a wide range of materials, from processing for traditional wooden construction methods to large cross-sections for non-residential buildings. The company has a flexible structure that can accommodate complex joints, curved surfaces, and other structures that require design flexibility, and is also attracting demand for "wooden structures that showcase the beauty of wood" while maintaining structural flexibility.

High-precision processing technology eliminates the need for on-site adjustment and processing of members, dramatically improving the efficiency of wooden construction. As a result, the reliability and usability of lumber will be greatly improved, and the conventional image of local lumber as "labor-intensive" and "unstable in quality" will be reversed. The company's factory is packed with mechanisms to evolve into the "timber of choice" for use in urban construction.

Regarding the key to promoting the use of regional timber, Naoyuki Otani, general manager of the company's Environmental Management Department, says, "We are actively promoting the use of JAS structural timbers and other materials, and are striving to provide highly reliable structural materials that meet the needs of buildings. By establishing a stable quality and supply system, we believe it is essential to provide high value-added structural materials that designers and builders can choose with confidence," he says.

The evolution of pre-cut processing has ushered in an era in which lumber grown in rural areas such as Toyama is being used as structural material for urban commercial and public buildings. In particular, high-precision and high-efficiency processing is indispensable to realize the "shortened construction period, stable quality, and on-site labor saving" required for urban wood construction.

Regarding the company's role in urban wood construction, General Manager Otani said, "We believe that the spread of wooden buildings that actively use local timber will not only contribute to the fight against global warming, but also to the healthy development of forests, the revitalization of local economies, and our role as a base for supplying timber to urban areas. We will promote the use of timber in public buildings and the use of local timber in large-scale wooden buildings, and will strengthen cooperation from upstream to downstream, not only for local production for local consumption, but also to build a high-quality local timber supply system that can meet the needs of urban areas," says Mr. Kurokawa, explaining his outlook.

The company has obtained ISO 9001 certification and has established a system for documenting and recording each process from material receipt to product shipment. The company's supply area is not limited to Toyama Prefecture, but extends to Ishikawa, Fukui, Niigata, and Gifu prefectures.

The processing process called "pre-cutting" bridges local timber to the urban site as "midstream. Midstream processors are,Stockyards mentioned in the previous article.It serves as the starting point for the conversion of materials supplied by the "Japan Agricultural Standard Association (JSA)" into JAS-certified and other high-quality building materials, and is the axis of rotation for the local ecosystem.

In Nanto City, where forests cover about 80% of the city area, a woody biomass boiler is already in operation, supplying heat to hot bath facilities and a heated swimming pool. This is a good example of a woody biomass heat supply business that utilizes unused wood from the mountains, such as thinned wood and lumber scraps, as fuel. Heat supplied by small- to medium-scale distributed wood chip boilers is considered an effective means of reducing transportation costs and promoting the use of the wood within the community.

The Western Toyama Forest Utilization Project Study Council has positioned the heat supply business as one of the important axes of forest resource utilization, and plans to apply for the Forestry Agency's "Ecosystem within the Region" subsidy program to install wood biomass boilers and other equipment. This is a concrete step toward increasing energy self-sufficiency through local initiative. The establishment of a regional energy system that does not rely on fossil fuels will not only contribute directly to decarbonization, but will also be important in building a regional economy that is resilient to changes in the external environment by promoting local production for local consumption of energy.

The regional ecosystem promoted by the Western Toyama Forest Utilization Project Study Council is a microcosm of the "circular forest economy" envisioned by the Platinum Forest Industry Initiative. Lumber produced upstream passes through stockyards to midstream processing processes such as lumber milling and pre-cutting, and is finally utilized within the region for wooden construction and heat supply. These demands then revitalize the upstream forestry industry.

There are various challenges to realizing this eco-system. These include competition from inexpensive imported timber, a shortage of forestry leaders, and the cost of installing and operating wood biomass heat utilization facilities. It will also require the understanding and participation of local residents and businesses, policy guidance (to promote the use of local timber and biomass), and the establishment of a financial mechanism to attract private investment.

It is essential for the success of this intra-regional eco-system that companies in the region utilize their strengths (branding of local lumber and advanced pre-cutting technology) to collaborate and contribute to the activities of the council. These activities are not merely economic activities, but are also linked to the social goal of fostering a "new forest culture. A future in which forests and communities coexist in harmony and resources circulate is beginning to emerge from western Toyama Prefecture.